Professional Aluminum Anodizing Services

Superior corrosion protection and aesthetic finishes for aluminum components. Type II and Type III anodizing, aerospace compliance, and multiple color options.

Upload drawings for feasibility and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

Advanced Aluminum Anodizing Technology

Anodizing creates a protective aluminum oxide layer through an electrochemical process, providing superior corrosion resistance without added weight or complexity. The process is controllable, repeatable, and delivers both protective and aesthetic benefits.

Unlike paint or powder coating, anodizing becomes part of the aluminum structure itself—creating a durable, long-lasting finish that resists scratching, weathering, and environmental degradation.

- Aluminum alloy selection for optimal anodizing results

- Thickness requirements and dimensional tolerances

- Color specification and anodize type (Type II or Type III)

- Masking requirements for non-anodized features

- Corrosion protection level requirements

Workflow: Upload design → 48h feedback → Quote with DFM notes → Anodizing production

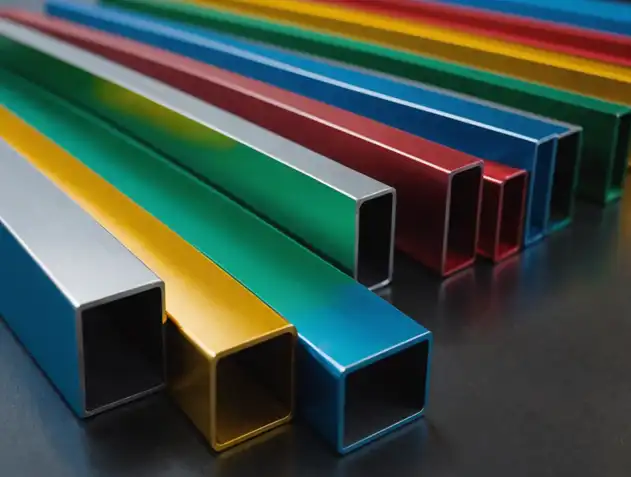

Work Samples

Representative examples of our anodizing capabilities. These samples showcase the quality and variety of anodized finishes we deliver.

Type II & Type III Options

Electrochemical Oxide Coating

Choose the anodizing type that matches your application requirements. Type II for general protection, Type III for extreme durability, with precise thickness control and color options.

Our anodizing systems comply with MIL-A-8625, ASTM B244, and aerospace standards with complete documentation and material traceability.

Anodizing Standards

- Type II thickness:0.5–2.5 mils

- Type III thickness:1–3 mils

- Lead time:3-5 business days

- Compliance:MIL-A-8625, ASTM B244

Types & Materials

- Aluminum alloys (6061, 5052, 7075) for optimal anodizing results

- Type II standard anodizing for general industrial applications

- Type III hard anodizing for aerospace and extreme-wear applications

- Multiple color options including clear, gold, bronze, black, and custom

- Precise oxide layer thickness verified to specification

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Products Using This Capability

Quality Assurance

100% inspection for coating uniformity, thickness, and color accuracy with full aerospace compliance.

Inspection & Verification

- 100% visual inspection for uniform oxide coating

- ASTM B244 thickness measurement verification

- Salt-spray testing per ASTM B117 for corrosion resistance

- Color accuracy verification and compliance confirmation

- First Article Inspection (FAI) with dimensional reporting

Aerospace Compliance

Our quality systems comply with MIL-A-8625, ASTM B244, and aerospace standards with complete documentation and material traceability.

Certification: ISO 9001 compliant quality management system with traceable inspection records.

Why Choose X-KPR for Anodizing

Combine aerospace-grade quality, rapid turnaround, and proven expertise with X-KPR's professional anodizing services.

Superior Corrosion Protection

Anodizing creates an oxide layer providing exceptional protection against corrosion, weathering, and environmental degradation.

Fast Turnaround

Efficient batch processing delivers anodized components in 3–5 business days with expedited options available.

Aerospace & Military Compliance

Full compliance with MIL-A-8625, ASTM B244, and aerospace standards with complete documentation and traceability.

Frequently Asked Questions

What is the difference between Type II and Type III anodizing?

What thickness does anodizing achieve?

What colors are available?

What is the turnaround time?

Is anodizing environmentally friendly?

Do you support aerospace applications?

Request a Quote

Specify your aluminum alloy, dimensions, quantity, and anodize type. We'll return feasibility feedback and pricing within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.