Metal Assembly Services for Industrial Applications

Complete metal assembly solutions combining fastening, welding, and sub-assembly integration. From prototype validation to high-volume production, we deliver consistent quality and precision.

Upload assembly drawings for DFM feedback and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

End-to-End Assembly Expertise

X-KPR brings decades of experience integrating components—from simple fastener assembly to complex, precision-engineered sub-assemblies requiring welding, alignment, and functional verification.

Whether you need assembly of components we fabricate or parts sourced from your suppliers, we manage every step with precision fixtures, skilled technicians, and comprehensive quality control.

- Assembly sequence and workflow optimization

- Fastener type and torque specifications

- Welding requirements and joint design

- Dimensional accuracy and alignment tolerances

- Quality inspection and testing protocols

Workflow: Upload assembly drawings → 48h feedback → Quote with DFM notes → Assembly production and testing

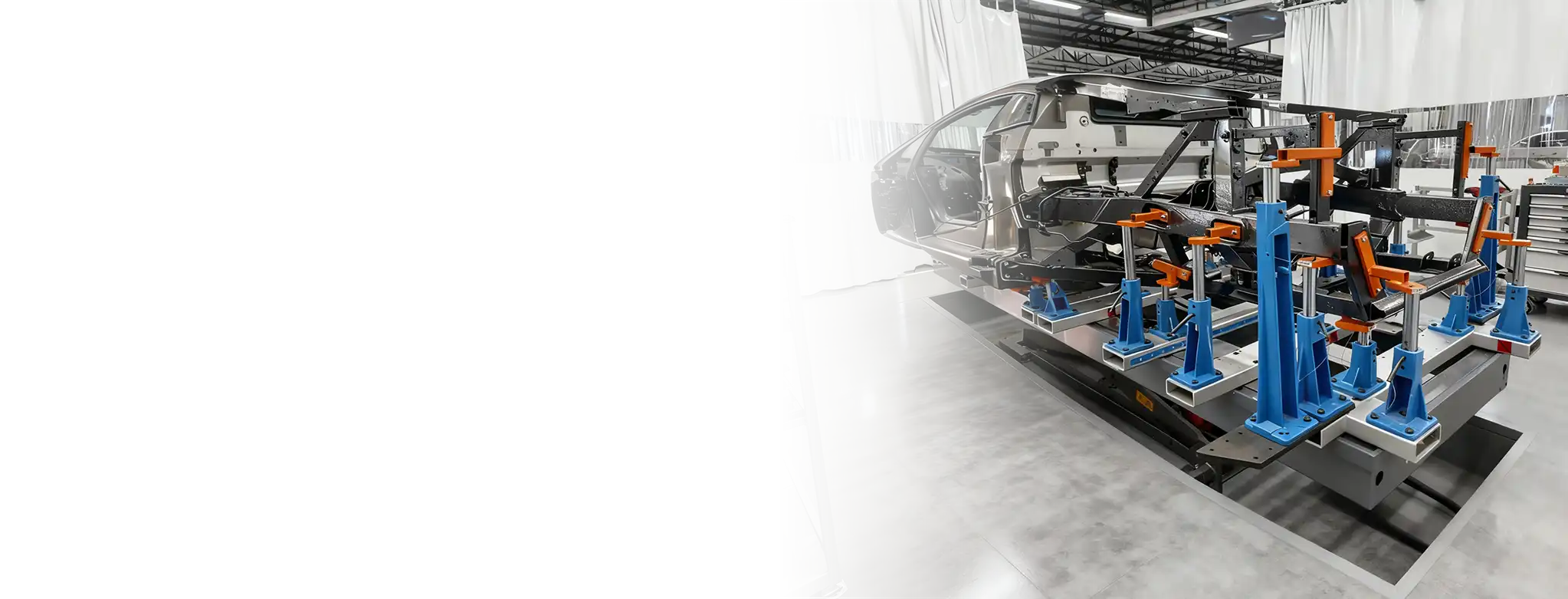

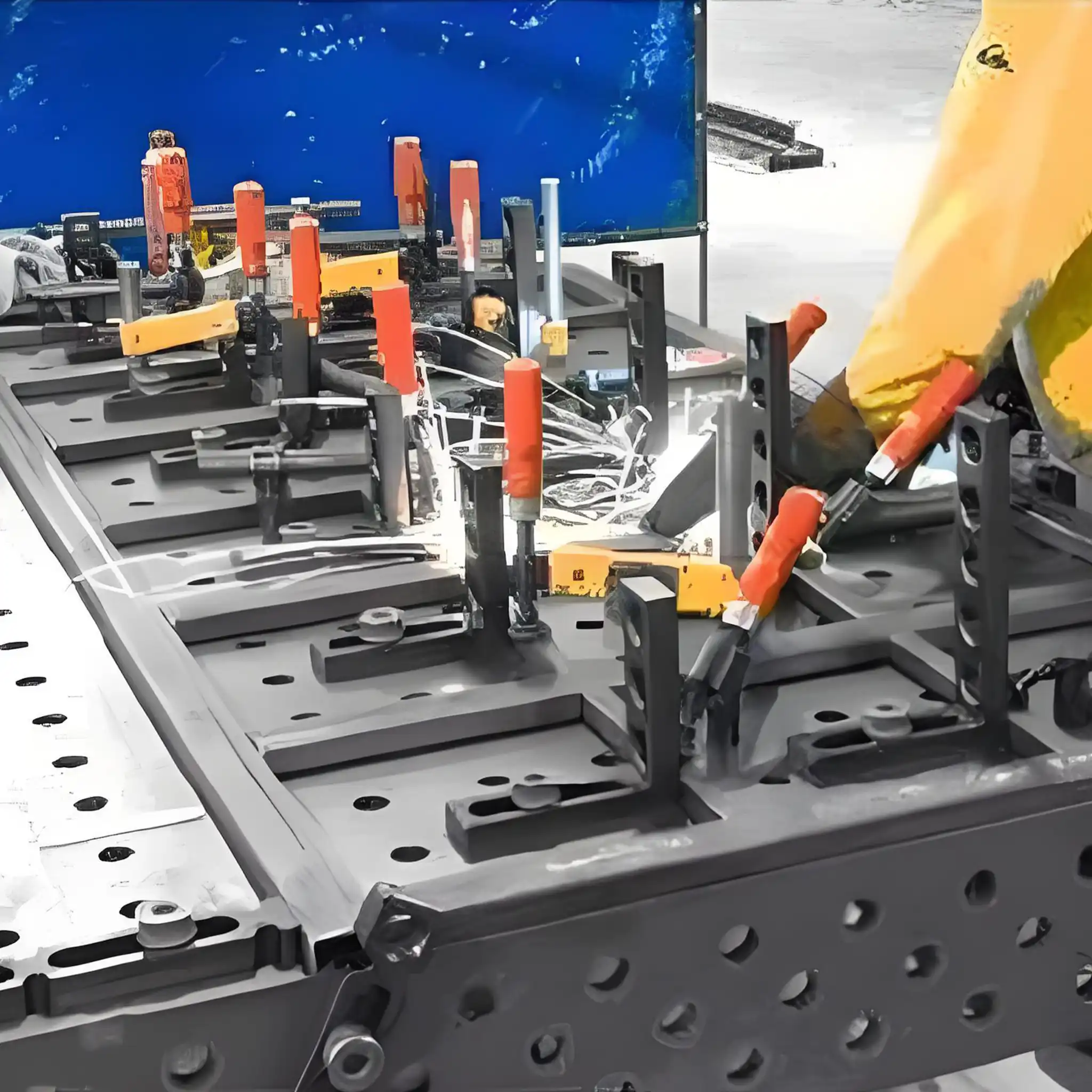

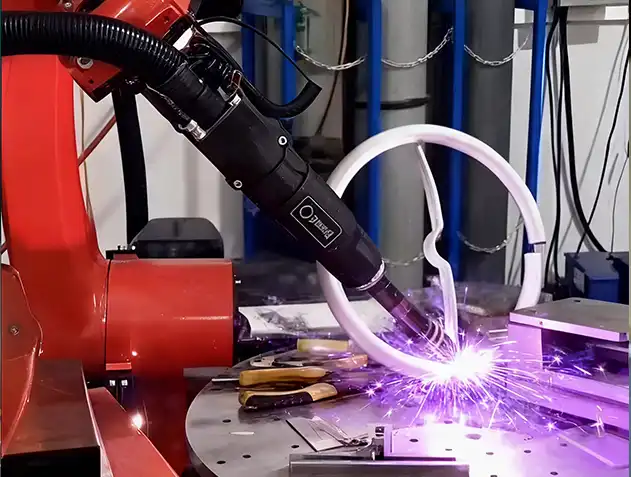

Work Samples

Representative examples of our assembly capabilities. These samples showcase the precision and complexity we deliver across all industries.

Assembly Process Capabilities

Comprehensive Assembly Solutions

Our assembly capabilities scale from prototypes to high-volume production with custom fixtures and processes optimized for your volume requirements. We handle everything from simple fastener insertion to complex multi-component integration.

Custom fixtures, documented procedures, and skilled technicians ensure every assembly meets exact specifications with consistent quality across entire production runs.

Capability Standards

- Complexity:Simple to complex multi-part assemblies

- Lead time:5-15 business days

- Volume:Prototype to high-volume production

- Testing:Dimensional, functional, torque verification

Assembly Processes

- Fastener assembly—manual and semi-automated insertion, riveting, threading

- Welding integration—MIG, TIG, and spot welding with precision positioning

- Sub-assembly building—multi-component integration into modular assemblies

- Quality verification—100% dimensional inspection, functional testing, and certification

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Products Using This Capability

Quality Assurance

Every assembly is verified for dimensional accuracy, proper fastening, weld quality, and functional performance.

Inspection & Verification

- 100% visual inspection for assembly accuracy

- Dimensional verification of critical features and alignment

- Fastener torque verification where specified

- Functional testing and operational validation

- First Article Inspection (FAI) with comprehensive documentation

Quality Documentation

Our quality protocols ensure consistency across prototypes, low-volume runs, and high-volume production. We provide FAI with comprehensive dimensional reports and functional testing documentation.

Certification: ISO 9001 compliant quality management system with traceable inspection records.

Why Choose X-KPR for Assembly Services

When assembly quality and efficiency matter, X-KPR delivers proven results with integrated fabrication and assembly capabilities.

Complete Integration

From raw components to finished assemblies, we handle fabrication, welding, fastening, and final integration under one roof.

Quality Control

Every assembly undergoes dimensional verification, functional testing, and quality inspection before shipment.

Proven Expertise

Over 20 years assembling components for automotive, electronics, medical, and industrial applications at volume.

Frequently Asked Questions

Can X-KPR handle complete assembly from fabrication through final integration?

What assembly processes do you support?

Do you provide quality inspection and testing?

Can you handle high-volume assembly?

How do you ensure repeatability and consistency?

What is your typical assembly turnaround?

Request a Quote

Share your assembly drawings, component specifications, and production requirements. We'll evaluate feasibility and provide a detailed quote within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.