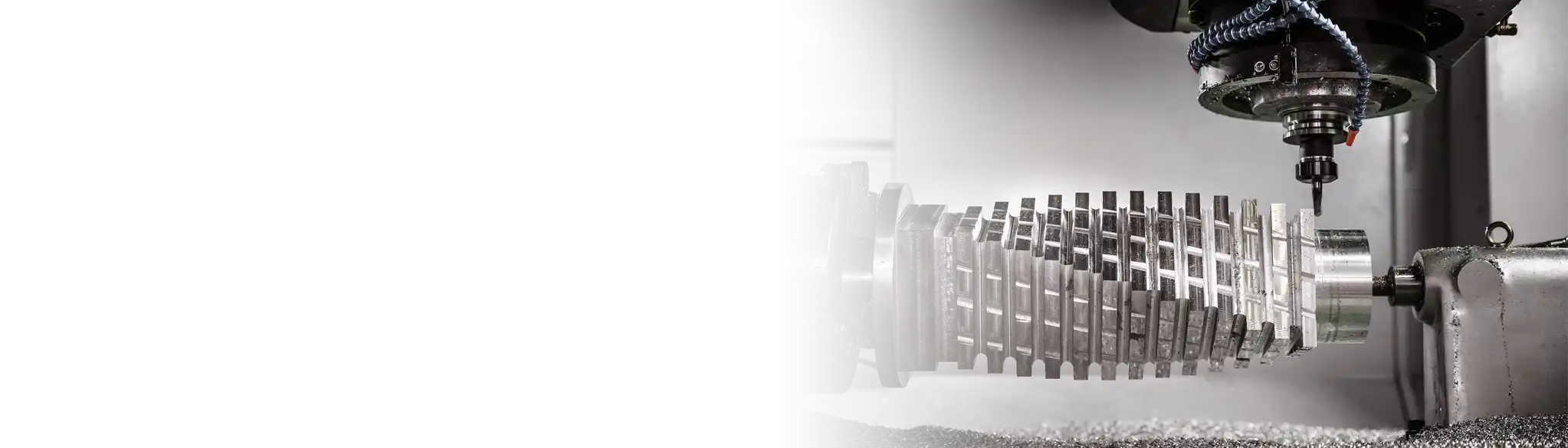

Precision CNC Milling Services

Engineering-driven CNC milling for complex part geometries, cavities, and detailed features. Tolerances ±0.05 mm, no tooling required—ideal for prototypes and production.

Upload STEP/IGES/DWG for DFM feedback and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

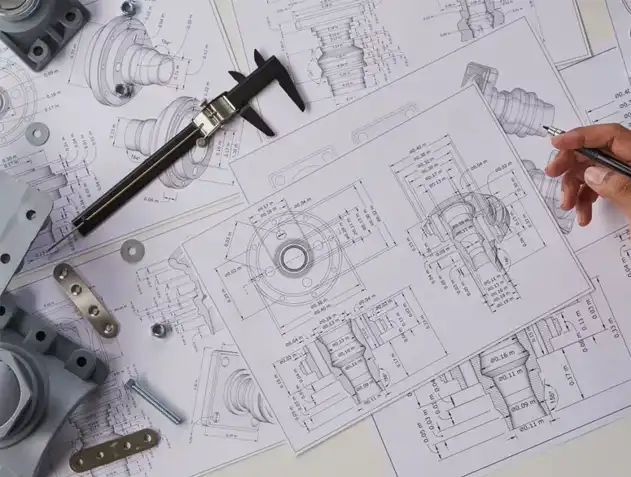

DFM Review & Engineering Support

Every CNC milling project begins with engineering analysis. We evaluate your geometry for optimal tool paths, machining efficiency, surface finish, and cost-effectiveness.

Our engineers provide design feedback within 48 hours, recommending modifications that improve manufacturability without compromising functionality.

- Material selection based on strength, thermal, and environmental requirements

- Feature sizing and positioning for precision machining

- Tool access and clearance for CNC cutting paths

- Surface finish specifications and critical dimension tolerances

- Edge relief and corner radii for manufacturability

Workflow: Upload design → 48h feedback → Quote with DFM notes → Prototype or production run

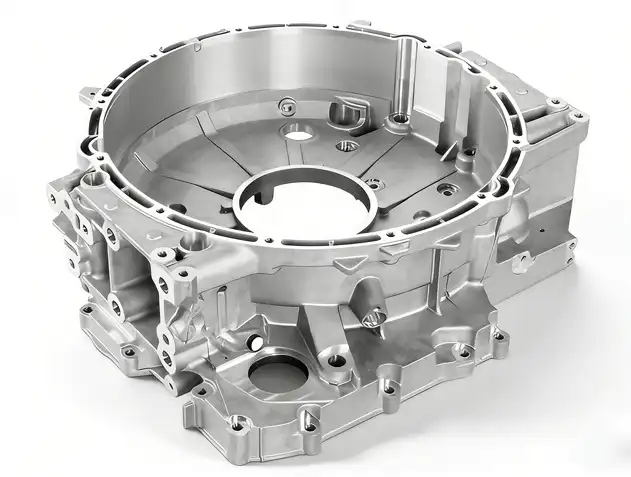

Work Samples

Representative examples of our CNC milling capabilities. These samples showcase the precision and versatility of our multi-axis CNC systems.

Technical Capabilities

Machining Process

Our multi-axis CNC milling systems deliver precision cuts for complex geometries, intricate cavities, and detailed features. No custom tooling required—ideal for rapid prototyping and production scaling.

Automated tool path optimization ensures efficient material removal and consistent quality across both prototype and volume quantities.

Precision Standards

- Tolerance:±0.05 mm standard

- Tight tolerance:±0.025 mm available

- Surface finish:Ra 0.8–3.2 µm

- Axes capability:3-axis to 5-axis

Process Advantages

CNC milling excels at complex geometries that would be prohibitively expensive with traditional tooling. Multi-axis capability enables undercuts and intricate details in a single setup.

- Multi-axis CNC milling for complex geometries

- Automated tool path optimization

- No custom tooling required

- Rapid prototyping and production runs

- Aluminum, steel, and specialty alloys

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Products Using This Capability

Quality Assurance

Dimensional verification with full traceability. CMM inspection available for critical features.

Inspection & Verification

- First Article Inspection (FAI) with comprehensive dimensional report

- In-process dimensional checks at key stages

- CMM verification for critical tolerances

- Surface finish verification and visual inspection

- Material certification and traceability documentation

Quality Documentation

We provide FAI reports, in-process inspection logs, Certificate of Analysis (CoA), Certificate of Conformance (CoC), and CMM reports on request.

Certification: ISO 9001 compliant quality management system with traceable inspection records.

Why Choose X-KPR for CNC Milling

When precision machining drives your project timeline, X-KPR combines engineering expertise, advanced equipment, and ISO 9001 quality control.

Engineering-Driven Design Review

Our engineers evaluate your part geometries for machining feasibility and cost efficiency—48h turnaround.

Multi-Axis CNC Capability

3-axis to 5-axis CNC mills handle complex geometries and intricate details without custom tooling.

ISO 9001 Quality Assurance

Dimensional verification with full traceability. CMM inspection available for critical features.

Frequently Asked Questions

What materials can be CNC milled?

What are the tolerances for CNC milling?

Can you handle complex geometries?

Is there a minimum or maximum part size?

Do you provide surface finishing?

What file formats do you accept?

Request a Quote

Provide part geometry, material specifications, tolerances, and quantities. We'll return DFM notes and a firm quote within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.