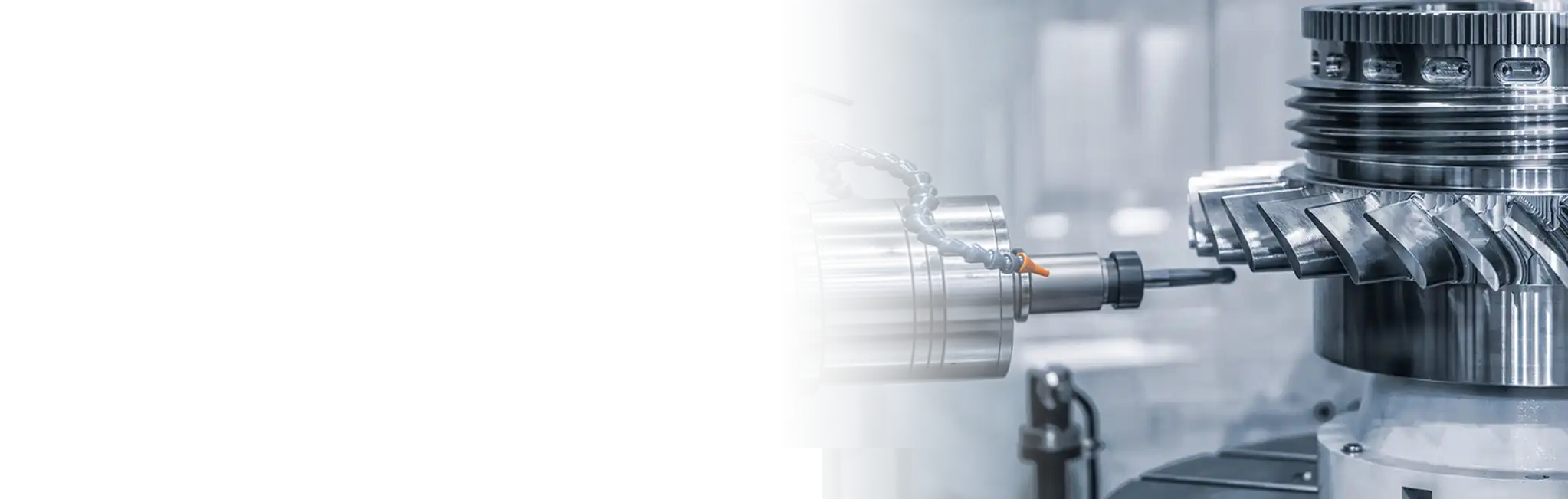

Prototyping to Production CNC Machining Services

Seamless scaling from rapid CNC prototyping to high-volume production. Validate designs in 3-5 business days, then scale to production with consistent quality and cost-effectiveness.

Upload STEP/IGES/DWG for DFM feedback and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

Single-Vendor Prototyping & Production

Moving from prototype to production with a single vendor eliminates multi-supplier coordination, reduces lead times, and ensures consistent quality throughout your entire supply chain. Same equipment, same processes, same precision.

Our CNC machines and quality systems are identical for both prototyping and production runs. This means your prototype validates against production-equivalent quality and tolerances.

- CAD model review and feasibility analysis

- Tolerance assessment and optimization recommendations

- Design refinements for manufacturability

- Tool path optimization and machine selection

- Prototype machining and dimensional verification

Workflow: Upload design → 48h feedback → Quote with DFM notes → Prototype or production run

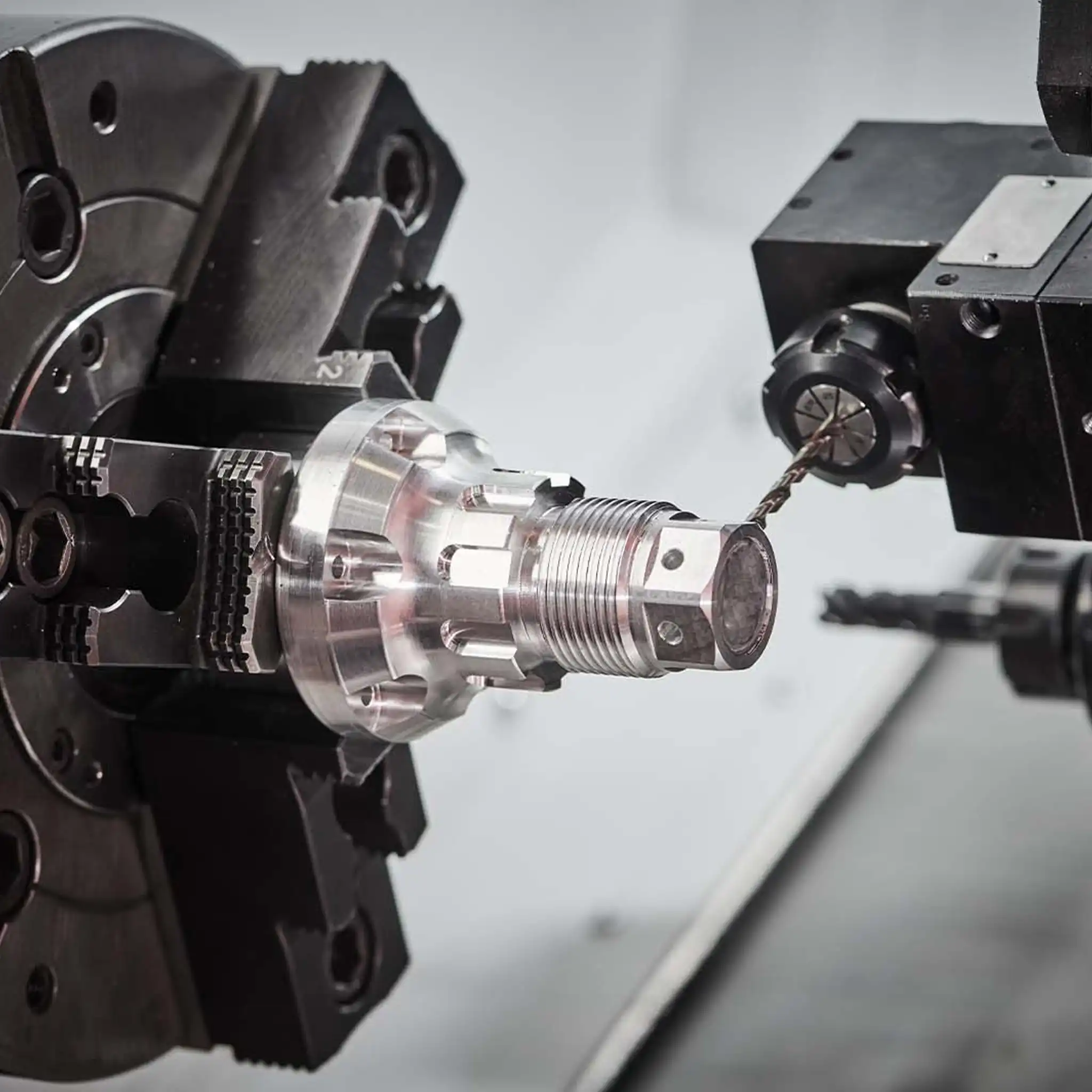

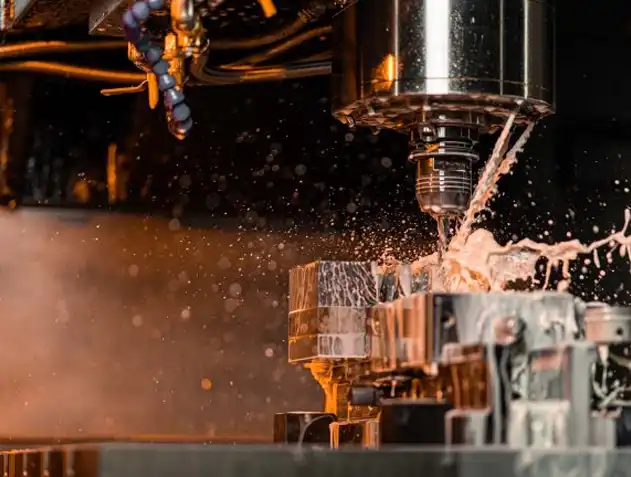

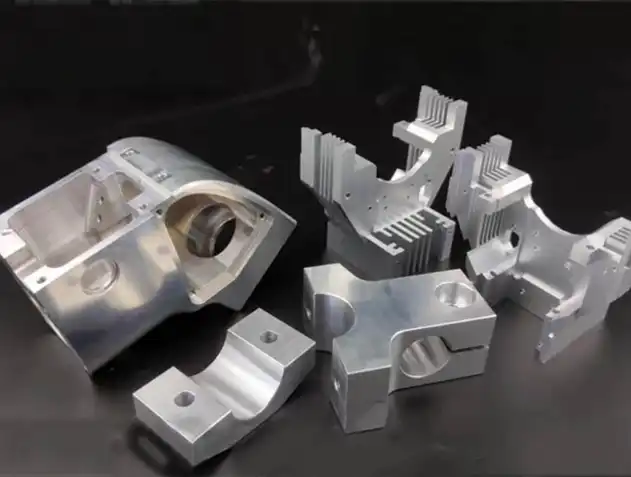

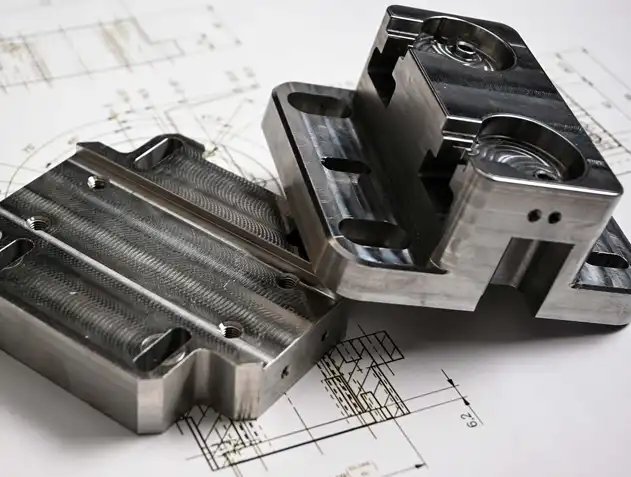

Work Samples

Representative examples of our CNC prototyping capabilities. These samples showcase the precision and quality we deliver from prototype through production.

Prototype-to-Production Process

Rapid Iteration & Validation

Fast turnaround on design validation. No tooling required, making rapid iteration ideal for design refinement and quick-turn feasibility. Test fit, function, and performance before committing to production volumes.

Our proven methodology ensures smooth transitions from design validation to full production, with consistent quality and optimized processes at every step.

Capability Standards

- Tolerance:±0.05 mm standard

- Lead time:3-5 business days

- Materials:All CNC-machinable metals

- Batch size:1 to 10,000+ units

The Process

- Design review and feasibility analysis within 24-48 hours

- Rapid prototype machining in 3-5 business days—no tooling required

- Design validation, testing, and DFM feedback

- Production preparation with optimized tool paths and fixtures

- High-volume production with consistent quality and process control

Scaling Options: Single Prototype → Small Batches (10-100 units) → Medium Runs (100-1,000 units) → High-Volume Production (1,000+ units)

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Products Using This Capability

Quality Assurance

Our prototypes meet identical quality standards as production parts, ensuring your design validation is accurate and reliable.

Inspection & Verification

- 100% dimensional verification for critical features

- Functional testing and assembly validation

- DFM feedback and design modification recommendations

- First Article Inspection (FAI) documentation

- Material certification and traceability

Production-Ready Quality

Every prototype undergoes full dimensional inspection and verification to confirm production readiness. Once approved, we transition seamlessly to production with optimized processes and rigorous quality control.

Certification: ISO 9001 compliant quality management system with traceable inspection records.

Why Choose X-KPR for CNC Prototyping

When rapid prototyping needs to scale to production, X-KPR combines speed, quality consistency, and engineering expertise.

Faster Time to Market

Prototype in days, not weeks. Accelerate design validation and move to production confidently without lengthy tooling cycles.

Cost-Effective Scaling

Single CNC vendor from prototype to production eliminates multi-supplier coordination. Consistent processes reduce per-unit costs at volume.

Quality Consistency

Same machines, same processes, same quality control from first prototype to final production run. Proven repeatability and reliability.

Frequently Asked Questions

How fast can you create prototypes?

Can I iterate on my prototype design?

How do you ensure consistent quality from prototype to production?

What happens if I need to modify the design before production?

Do you handle low-volume production runs?

What materials do you support for prototyping?

Request a Quote

Upload your design files and let us evaluate feasibility and provide a prototype quote. We'll get back to you within 48 hours with DFM recommendations and pricing.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.