CNC Turning Services for Industrial Applications

High-precision CNC turning for shafts, bushings, and rotational components. Tolerances ±0.05 mm, ideal for mechanical assemblies, connectors, and precision fittings.

Upload STEP/IGES/DWG for DFM feedback and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

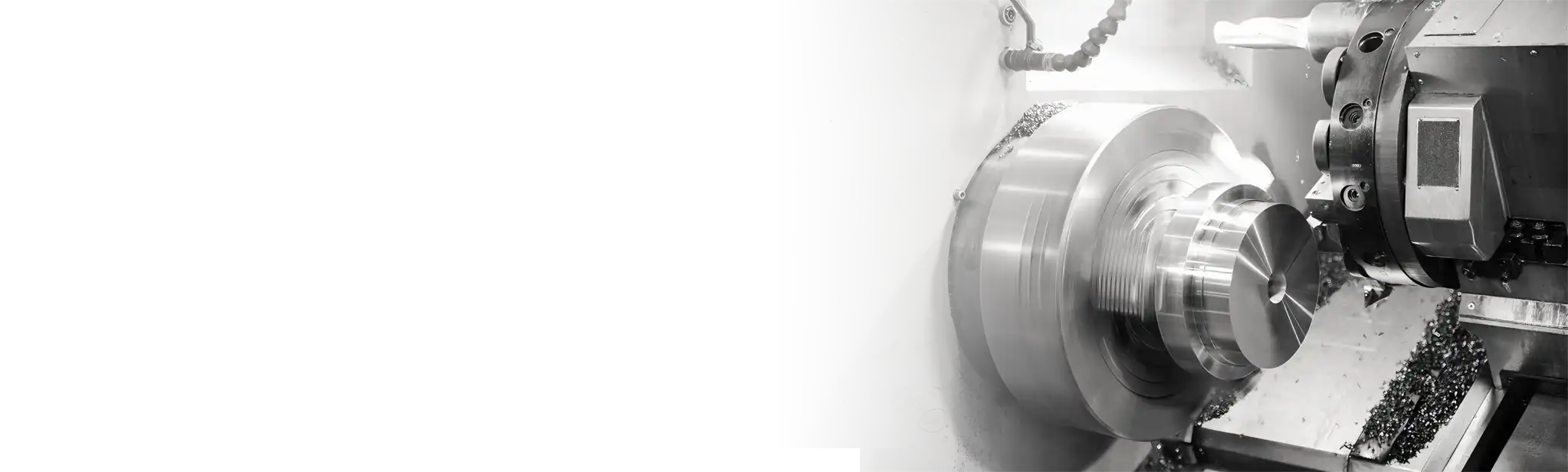

Advanced CNC Lathe Systems

Our state-of-the-art CNC lathes deliver exceptional precision for rotational components, shafts, and cylindrical geometries. From small precision connectors to large mechanical shafts, CNC turning offers unmatched accuracy and efficiency.

Unlike traditional manual turning, CNC automation requires no custom tooling—making it ideal for prototypes, low-volume runs, and complex geometries with threads, tapers, and multiple diameters.

- Material selection based on strength, wear, and thermal requirements

- Diameter and length specifications for rotational components

- Thread pitch and type for internal/external threading

- Taper angles and conical sections for precise fit

- Surface finish specifications and critical dimension tolerances

Workflow: Upload design → 48h feedback → Quote with DFM notes → Prototype or production run

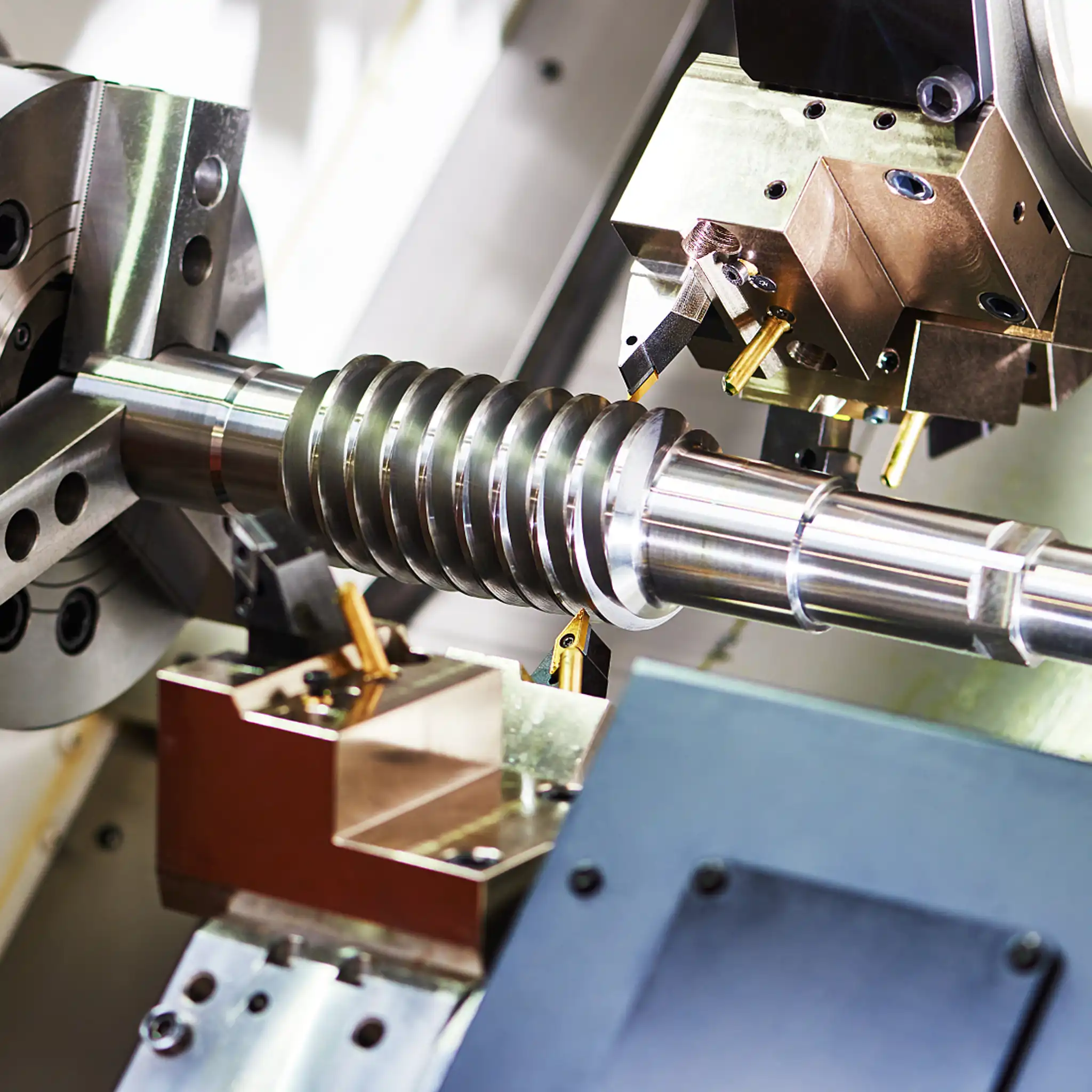

Work Samples

Representative examples of our CNC turning capabilities. These samples showcase the precision and versatility of our CNC lathe systems.

Technical Capabilities

Precision & Material Capabilities

Our CNC turning systems excel across diverse materials and complexities. Single-setup processing eliminates repositioning errors and accelerates production for both prototype and volume quantities.

Automated tool control and spindle programming maximize production throughput while maintaining tight tolerance control across high-volume production runs.

Precision Standards

- Tolerance:±0.05 mm standard

- Lead time:5-7 business days

- Materials:All CNC-turnable metals

- Surface finish:Ra 0.4–1.6 µm

Materials & Capabilities

- Aluminum and brass—fast cutting speeds for lightweight applications

- Steel and stainless steel—precision turning for mechanical components

- Titanium and specialty alloys—for aerospace and high-performance use

- Precision tolerances—±0.05 mm diameter and length control

- Thread and taper capability—internal/external threads and complex profiles

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Products Using This Capability

Quality Assurance

100% inspection for dimensional accuracy, surface finish, and material specifications.

Inspection & Verification

- 100% dimensional verification for critical diameters and lengths

- Thread pitch and surface finish verification

- Automated tool wear compensation for tolerance consistency

- First Article Inspection (FAI) with comprehensive reports

- Material certification and traceability documentation

Quality Documentation

Our precision measurement tools verify diameters, lengths, threads, and critical features to ensure your parts meet exact specifications.

Certification: ISO 9001 compliant quality management system with traceable inspection records.

Why Choose X-KPR for CNC Turning

When CNC turning needs to be fast, precise, and cost-effective, X-KPR delivers proven results with rapid turnaround.

Cost-Effective Solutions

Optimized tool control and cutting parameters reduce production costs. Flexible pricing scales with your production volume.

Fast Turnaround

From design upload to shipment in 5–7 business days. Expedited runs available for urgent projects.

Precision & Repeatability

Automated processes ensure consistent part quality and dimensional accuracy across entire production runs.

Frequently Asked Questions

What materials can be CNC turned?

What are the tolerances for CNC turning?

Can you handle threaded and tapered sections?

Is there a minimum or maximum part length?

Do you provide secondary finishing?

What file formats do you accept?

Request a Quote

Tell us your material, component geometry, tolerance requirements, and quantity. We'll return DFM feedback and a firm quote within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.