End-to-End Custom Tube Fabrication Services

Engineering-driven tube product manufacturing—from design review through production delivery.

Upload STEP/IGES/DWG for DFM feedback and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

Design-for-Manufacturability Partnership

Your tube product begins with honest engineering collaboration. We review your design for manufacturability, recommend material selection, and optimize geometry for cost and quality.

Our engineers provide detailed DFM feedback within 48 hours, identifying potential issues early and suggesting refinements that improve both performance and manufacturing efficiency.

- Functional requirements and performance specifications

- Material preferences (steel, stainless, aluminum, copper, titanium)

- Load conditions, pressure ratings, and stress analysis

- Assembly configuration: individual tubes or complete products

- Surface finish: as-fabricated, anodized, painted, or polished

- Quantity and phased delivery requirements

Workflow: Upload design → 48h feedback → Quote with DFM notes → Prototype or production run

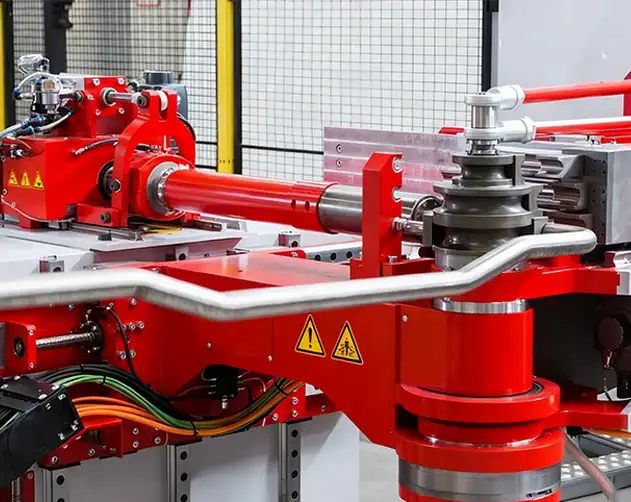

Work Samples

Representative examples of our custom tube fabrication capabilities. These samples showcase integrated manufacturing from cutting through final assembly.

Integrated Manufacturing Capabilities

Complete Tube Processing

All tube processing steps—cutting, bending, flaring, welding, finishing—coordinated under one roof. This eliminates vendor coordination complexity and accelerates your project timeline.

Single-source manufacturing ensures consistent quality control across all fabrication steps, from raw material to finished assembly.

Project Standards

- Design review:48h DFM feedback

- Prototype lead time:5–10 business days

- Production scaling:10–1000+ units

- Quality standard:ISO 9001 certified

Manufacturing Capabilities

We integrate precision fabrication processes to deliver complete tube products that meet tight specifications and demanding timelines.

- Laser cutting with ±0.05mm accuracy

- CNC mandrel bending for smooth curves

- Precision flaring and end forming

- TIG/MIG welding with full traceability

- Surface finishing: powder coating, anodizing, polishing

- Complete assembly and testing services

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Products Using This Capability

Quality Assurance

Complete documentation and traceability from material certification through final shipment.

Inspection & Verification

- First Article Inspection (FAI) for every new part

- In-process dimensional checks at key stages

- Weld procedure specifications (WPS) and verification

- Surface finish and assembly quality inspection

- Comprehensive visual inspection before shipping

Quality Documentation

We provide FAI reports, in-process inspection logs, material traceability certificates, weld documentation, dimensional inspection reports, and compliance certifications.

Certification: ISO 9001 compliant quality management system with traceable inspection records.

Why Choose X-KPR for Custom Tube Fabrication

When your tube product needs engineering support, precision manufacturing, and reliable delivery, X-KPR combines expertise, integrated capability, and ISO 9001 quality.

True Engineering Partnership

Our team collaborates on your design from concept through production release. Honest feedback and manufacturability guidance.

Integrated Manufacturing Under One Roof

All tube processing steps—cutting, bending, flaring, welding, finishing—coordinated by a single team.

ISO 9001 Quality & Full Traceability

Complete documentation and traceability from material certification through final shipment.

Frequently Asked Questions

How does the DFM process work?

Can you handle prototype and low-volume production?

What is your typical lead time for custom fabrication?

What quality documentation do you provide?

Request a Quote

Upload your design or describe your tube product concept. We'll evaluate for manufacturability and return a detailed quotation within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.