Professional Metal Plating & Sandblasting Services

Expert surface preparation and electroplating for superior corrosion protection. Nickel, chrome, and zinc plating, professional sandblasting, and aerospace compliance.

Upload drawings for feasibility and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

Advanced Plating & Surface Preparation Technology

Electroplating deposits a protective metal coating onto component surfaces through an electrochemical process, providing superior corrosion protection and enhanced appearance. Our precision equipment controls coating thickness and uniformity for consistency across all components.

Combined with professional sandblasting surface preparation, our integrated process ensures optimal coating adhesion, maximum corrosion resistance, and long-lasting protection in demanding aerospace, industrial, and marine environments.

- Material type and existing surface condition

- Plating type (nickel, chrome, zinc) and thickness requirements

- Masking requirements for non-plated or preserved surfaces

- Pre-treatment and surface preparation specifications

- Adhesion and corrosion protection requirements

Workflow: Upload design → 48h feedback → Quote with DFM notes → Plating production

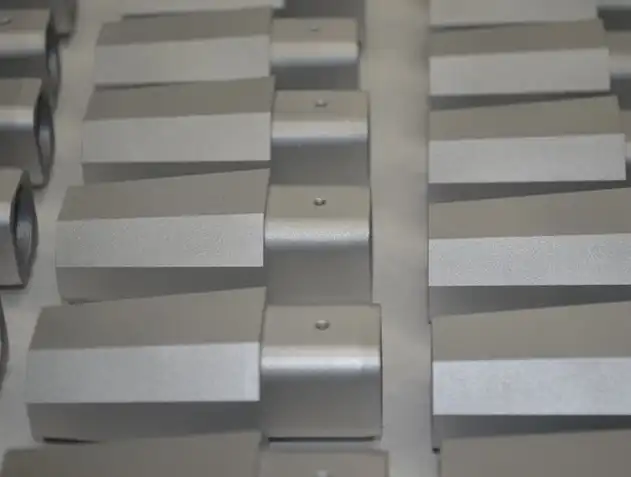

Work Samples

Representative examples of our plating and sandblasting capabilities. These samples showcase superior corrosion protection across applications.

Plating Types & Surface Prep

Electroplating Process

Choose the plating solution matched to your application. Professional-grade electroplating and surface preparation equipment deliver superior corrosion protection and quality finishes across all industries.

Our systems comply with ASTM B571, ASTM B117 salt-spray testing, and aerospace specifications with complete documentation and material traceability.

Plating Standards

- Nickel plating:0.0005–0.003 inches

- Chrome plating:0.00005–0.001 inches

- Lead time:5-7 business days

- Compliance:ASTM B571, ASTM B117

Plating Options

- Nickel plating for superior corrosion protection and aerospace applications

- Chrome plating for enhanced wear resistance and decorative finishes

- Zinc plating for cost-effective general corrosion protection

- Professional sandblasting prep maximizing coating adhesion

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Products Using This Capability

Quality Assurance

100% inspection for coating uniformity, thickness, and adhesion integrity with full aerospace compliance.

Inspection & Verification

- 100% plating thickness measurement and verification

- ASTM B117 salt-spray testing for corrosion resistance

- ASTM B571 adhesion testing and compliance verification

- Visual inspection for uniformity and defects

- Material certification and traceability documentation

Aerospace Compliance

Our quality systems comply with ASTM B571, ASTM B117 salt-spray testing, and aerospace specifications with complete documentation and material traceability.

Certification: ISO 9001 compliant quality management system with traceable inspection records.

Why Choose X-KPR for Plating & Sandblasting

Combine aerospace-grade quality, superior corrosion protection, and proven expertise with X-KPR's professional plating services.

Superior Corrosion Protection

Professional plating and surface preparation deliver long-lasting protection against rust, oxidation, and environmental degradation.

Fast Turnaround

Efficient batch processing delivers plated and prepared components in 5–7 business days with expedited options available.

Aerospace & Military Compliance

Full compliance with ASTM B571, MIL specifications, and aerospace standards with complete documentation and traceability.

Frequently Asked Questions

What plating types are available?

What plating thickness is standard?

How does sandblasting improve plating?

What surface finish does sandblasting achieve?

Do you support aerospace specifications?

What is the turnaround time?

Request a Quote

Specify your material, plating type, thickness requirements, and quantity. We'll return feasibility feedback and pricing within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.