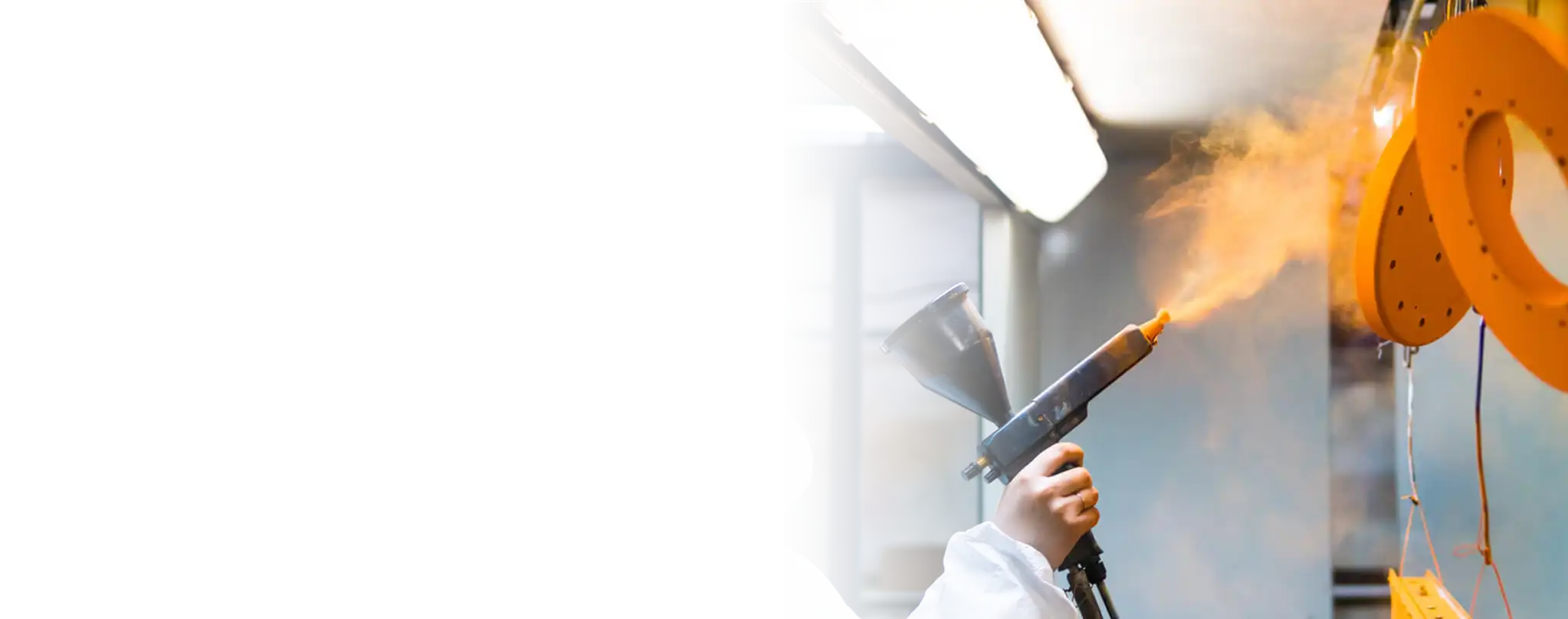

Powder Coating Services for Industrial Applications

Professional powder coating with superior corrosion resistance, durability, and custom color options. Zero VOC emissions, environmentally friendly, and ideal for industrial, architectural, and consumer applications.

Upload drawings for feasibility and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

Thermosetting Powder Coating Technology

Our electrostatic powder coating systems deliver uniform, high-quality finishes with exceptional durability and corrosion resistance. The thermosetting process creates a hard, protective coating that resists chemicals, UV exposure, and environmental degradation.

Unlike traditional liquid paint, powder coating produces zero VOCs, reduces waste, and creates stronger, more durable finishes—making it the preferred choice for industries requiring superior protection and environmental compliance.

- Material type and substrate preparation requirements

- Dimensional requirements and tight tolerance areas

- Color selection and finish specifications

- Masking and preservation of threads or contact surfaces

- Environmental and chemical resistance requirements

Workflow: Upload design → 48h feedback → Quote with DFM notes → Powder coating production

Work Samples

Representative examples of our powder coating capabilities. These samples showcase durable finishes protecting components across industries.

Finish Options & Customization

Advanced Powder Application Systems

Choose from hundreds of color and finish options. Professional-grade equipment and expertise ensure consistent, durable finishes that protect and beautify your metal components.

Our systems provide complete documentation including material certifications, coating specifications, and environmental compliance reports.

Coating Standards

- Thickness:1.5–3.5 mils (38–89 microns)

- Lead time:3-5 business days

- VOC emissions:Zero

- Finish options:Matte, gloss, textured, metallic

Color & Finish Options

- Standard colors—wide selection of RAL and Pantone colors

- Custom colors—color matching and custom formulations available

- Finish types—gloss, matte, textured, metallic, and specialty finishes

- Thickness control—precise coating thickness (1.5–3.5 mils) for optimal protection

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Products Using This Capability

Quality Assurance

100% inspection for color accuracy, coating uniformity, and adhesion integrity.

Inspection & Verification

- 100% visual inspection for coating uniformity and color accuracy

- ASTM D3359 adhesion testing to ensure proper coating adhesion

- Coating thickness measurement using precision gauges

- Pre and post-treatment documentation

- Material certifications and environmental compliance reporting

Quality Control

Every powder-coated part is inspected for color accuracy, coating uniformity, and adhesion integrity. Our quality systems verify coating thickness, color matching, and environmental compliance to ensure your parts meet exact specifications.

Certification: ISO 9001 compliant quality management system with traceable inspection records.

Why Choose X-KPR for Powder Coating

Combine durability, environmental responsibility, and fast turnaround with X-KPR's professional powder coating services.

Eco-Friendly Solution

Powder coating produces zero VOCs and minimal waste, making it an environmentally responsible finishing alternative.

Rapid Turnaround

Fast curing cycles and efficient batch processing deliver finished components in 3–5 business days.

Durable Protection

Superior corrosion resistance and weather protection extend component lifespan and reduce maintenance costs.

Frequently Asked Questions

What materials can be powder coated?

What thickness is achieved with powder coating?

What colors and finishes are available?

How long does the process take?

Is powder coating environmentally friendly?

What file formats do you accept?

Request a Quote

Specify your material, dimensions, quantity, and color preferences. We'll return feasibility feedback and pricing within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.