Precision Press Brake Bending Services

Engineering-driven CNC press brake bending for brackets, enclosures, and structural components—tight tolerances, repeatable geometry, and dependable lead times.

Upload STEP/IGES/DWG for DFM feedback and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

DFM Review & Engineering Support

Every bending project begins with engineering analysis. We evaluate your geometry for optimal bend sequences, tooling selection, springback compensation, and cost efficiency.

Our engineers provide design feedback within 48 hours, recommending modifications that improve manufacturability without compromising functionality.

- Bend sequence optimization to minimize material handling

- Bend radius selection based on material and thickness

- Springback compensation for angle accuracy

- Fixture design for repeatable geometry across production runs

- Edge distance and mounting point verification

Workflow: Upload design → 48h feedback → Quote with DFM notes → Prototype or production run

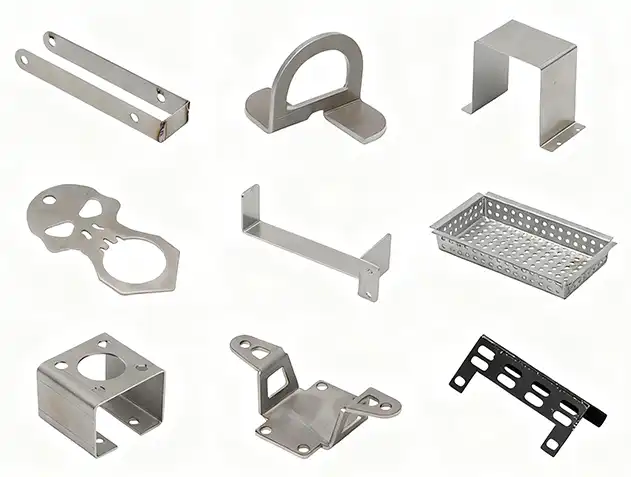

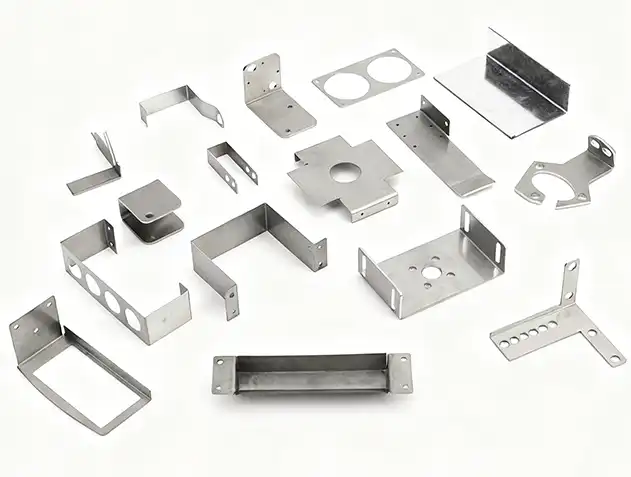

Work Samples

Representative examples of our press brake bending capabilities. These samples showcase the precision and versatility of our CNC bending systems.

Technical Capabilities

Bending Process

Our CNC press brake systems with automated bend sequences deliver precision bends with ±0.5 degree angle control and ±0.5 mm edge distance accuracy. Single-setup processing eliminates repositioning errors and accelerates production for both prototype and volume quantities.

Custom fixture design ensures repeatable geometry across all units, making CNC bending ideal for high-volume production where consistency is critical.

Precision Standards

- Bend angle tolerance:±0.5 degrees

- Edge distance tolerance:±0.5 mm

- Material thickness:0.5 mm – 12 mm

- Bend radius:1.5x – 10x thickness

Materials

We process a wide range of sheet metal materials, from standard carbon steel to exotic alloys. Material selection guidance provided during engineering review.

- Mild steel and carbon steel

- Stainless steel (304, 316, 316L)

- Aluminum alloys (6061, 5052)

- Copper and brass

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Products Using This Capability

Quality Assurance

Dimensional verification with full traceability. CMM inspection available for critical features.

Inspection & Verification

- First bend angle and edge distance verification

- In-process dimensional checks during production

- Final assembly dimensional verification against drawing specs

- Springback testing for new bend geometries

- CMM inspection available for complex multi-bend components

Quality Documentation

We provide FAI reports, in-process inspection logs, Certificate of Analysis (CoA), Certificate of Conformance (CoC), and CMM reports on request.

Certification: ISO 9001 compliant quality management system with traceable inspection records.

Why Choose X-KPR for Press Brake Bending

When precision bending drives your project timeline, X-KPR combines engineering expertise, advanced equipment, and ISO 9001 quality control.

Integrated Fabrication

Combined with laser cutting and welding, we deliver complete sheet metal assemblies in one location.

Rapid Programming

CNC programming and fixture setup completed within 48 hours of design approval.

Volume Scaling

Fixture investment amortized across production volume, delivering cost-effective runs from small to large quantities.

Frequently Asked Questions

What bend tolerances can you achieve?

What is the minimum and maximum bend radius?

Can you bend stainless steel and aluminum?

Do you offer multi-bend geometries?

Request a Quote

Provide bend geometry, material specifications, and quantities. We'll return DFM notes and a firm quote within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.