Sheet Metal Enclosure Fabrication Services

Engineering-driven enclosure fabrication—cutting, bending, welding, finishing, and assembly. Custom electronics housings, equipment cabinets, and protective panels.

Upload STEP/IGES/DWG for DFM feedback and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

DFM Review & Engineering Support

Custom enclosures demand precision, aesthetics, and integrated functionality. Our complete fabrication workflow—from laser cutting through final assembly—ensures consistency, eliminates multi-vendor coordination delays, and delivers quality-assured enclosures ready for deployment.

Our engineering team partners with you from concept through production, evaluating thermal management, cable routing, component mounting, environmental protection, and aesthetic requirements.

- Enclosure geometry and structural integrity analysis

- Thermal management and airflow optimization

- Cable routing, ventilation, and access planning

- Mounting provision design for internal components

- Material selection for environment and durability requirements

Workflow: Upload design → 48h feedback → Quote with DFM notes → Prototype or production run

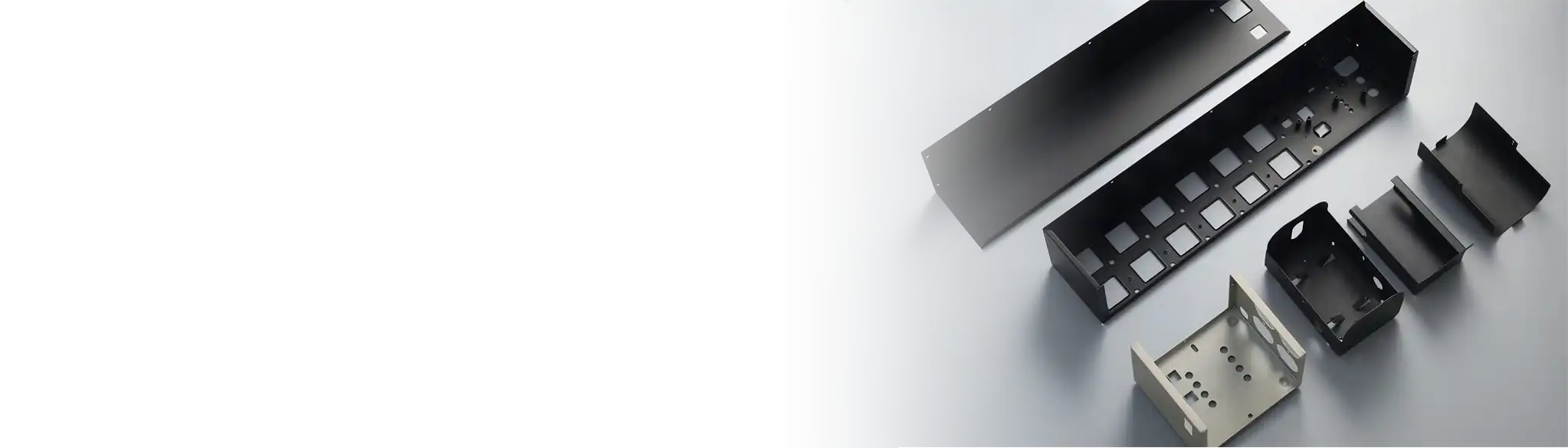

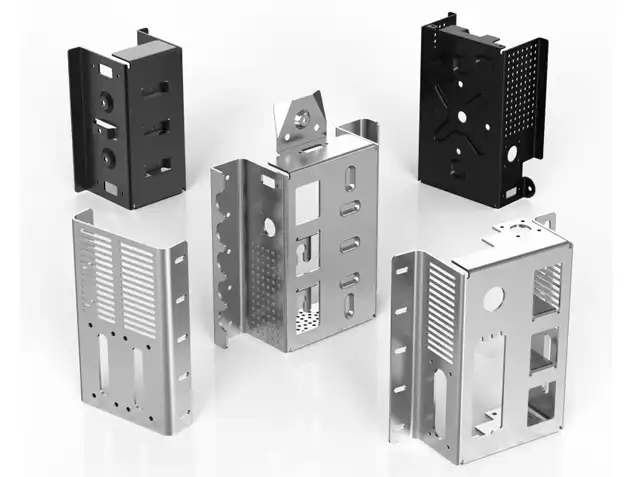

Work Samples

Representative examples of our sheet metal enclosure capabilities. These samples showcase our integrated fabrication and finishing processes.

Technical Capabilities

Integrated Fabrication Process

Our integrated workflow handles diverse enclosure requirements: laser cutting for precision geometry, CNC bending for structural integrity, TIG/MIG welding for assembly, and powder coating or anodizing for environmental protection.

We handle hardware installation, wiring, and mounting of internal components, delivering complete, tested enclosures ready for field installation.

Precision Standards

- Material thickness:0.5 mm – 12 mm

- Cutting tolerance:±0.1 mm (laser)

- Bend tolerance:±0.5 degrees

- Surface finishes:Powder coat, anodize, plate

Materials

We process a wide range of sheet metal materials, from standard carbon steel to exotic alloys. Material selection guidance provided during engineering review.

- Mild steel and carbon steel

- Stainless steel (304, 316, 316L)

- Aluminum alloys (6061, 5052)

- Copper and brass

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Products Using This Capability

Quality Assurance

End-to-end quality control throughout entire fabrication process. Each stage inspected and verified.

Inspection & Verification

- First Article Inspection with dimensional and assembly verification

- In-process welding and finishing quality checks

- Dimensional verification of complete enclosure assembly

- Testing of mechanical operations (doors, panels, latches)

- Component integration and functional verification

Quality Documentation

We provide FAI reports, assembly documentation, Certificate of Analysis (CoA), Certificate of Conformance (CoC), and traceability records.

Certification: ISO 9001 compliant quality management system with traceable inspection records.

Why Choose X-KPR for Sheet Metal Enclosures

When custom enclosures need precision, speed, and seamless integration, X-KPR delivers single-source accountability and complete quality control.

Single-Source Partnership

One vendor for complete enclosure design, fabrication, finishing, and assembly. Simplified coordination and accountability.

End-to-End Quality Control

Consistent quality throughout entire fabrication process. Each stage inspected and verified before moving to next phase.

Rapid Delivery

Integrated workflow from cutting through final assembly completes enclosures faster than coordinating multiple vendors.

Frequently Asked Questions

Can you design custom enclosures from scratch?

What finishing options are available?

Can you integrate components into the enclosure?

What is the lead time for custom enclosures?

Request a Quote

Provide enclosure dimensions, material, finishing requirements, and component integration needs. We'll return DFM feedback and a firm quote within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.