Precision Sheet Metal Laser Cutting Services

Engineering-driven fiber laser cutting for flat patterns, holes, and complex geometries—tight tolerances, rapid prototyping, and production efficiency.

Upload STEP/IGES/DWG for DFM feedback and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

DFM Review & Engineering Support

Our fiber laser systems deliver exceptional precision for a wide range of sheet metal materials. From delicate electronics enclosure blanks to heavy-duty structural brackets, laser cutting offers unmatched speed, accuracy, and flexibility.

Unlike traditional punching or waterjet, laser cutting requires no physical tooling—making it ideal for prototypes, low-volume runs, and complex geometries that would be prohibitively expensive to tool.

- Material selection based on strength and environmental requirements

- Hole sizing and placement for fasteners and alignment features

- Edge relief and corner radii for manufacturability

- Nesting optimization to minimize material waste

- Surface finish requirements and edge quality specifications

Workflow: Upload design → 48h feedback → Quote with DFM notes → Prototype or production run

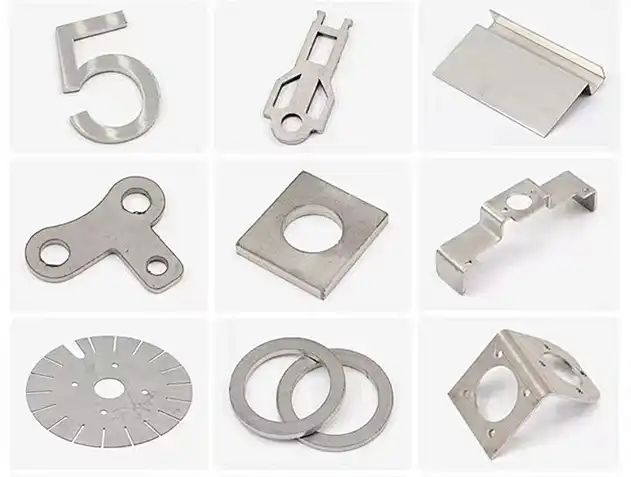

Work Samples

Representative examples of our sheet metal laser cutting capabilities. These samples showcase precision, clean edges, and minimal burring.

Technical Capabilities

Laser Cutting Process

Our high-power fiber laser systems deliver ±0.1 mm precision for intricate patterns, tight holes, and complex geometries. Automated nesting and cutting workflows maximize material efficiency while maintaining tight tolerance control across high-volume production runs.

No tooling required makes laser cutting ideal for rapid prototyping with 24-48h rush turnaround available for urgent design validation.

Precision Standards

- Cutting tolerance:±0.1 mm (holes/features)

- Material thickness:0.5 mm – 12 mm

- Edge finish:Clean, minimal burr

- Lead time:5–7 business days

Materials

We cut carbon steel, stainless steel, aluminum, and copper. Material selection depends on your application with thickness range from 0.5 mm to 12 mm.

- Mild steel and carbon steel

- Stainless steel (304, 316, 316L)

- Aluminum alloys (6061, 5052)

- Copper and brass

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Products Using This Capability

Quality Assurance

100% inspection for dimensional accuracy, edge quality, and material specifications.

Inspection & Verification

- 100% visual inspection for dimensional accuracy

- Automated measurement of critical features and hole positioning

- Edge quality verification and burr assessment

- First Article Inspection (FAI) with dimensional report for production runs

- Material certification and traceability documentation

Quality Documentation

We provide FAI reports with comprehensive dimensional reports, Certificate of Conformance (CoC), and material certifications.

Certification: ISO 9001 compliant quality management system with traceable inspection records.

Why Choose X-KPR for Sheet Metal Laser Cutting

When sheet metal laser cutting needs to be fast, precise, and cost-effective, X-KPR delivers proven results with rapid turnaround and uncompromising quality.

Cost-Effective Production

No tooling costs for prototypes and low-volume runs. Flexible pricing scales with your production volume.

Fast Turnaround

From design upload to shipment in 5–7 business days. Expedited runs available for urgent projects.

Precision & Repeatability

Automated processes ensure consistent part quality and dimensional accuracy across entire production runs.

Frequently Asked Questions

What materials can be laser cut?

What are the tolerances for laser cutting?

Is there a minimum or maximum thickness?

Can you handle rapid prototyping?

Request a Quote

Provide material, thickness, part geometry, and quantity. We'll return DFM feedback and a firm quote within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.