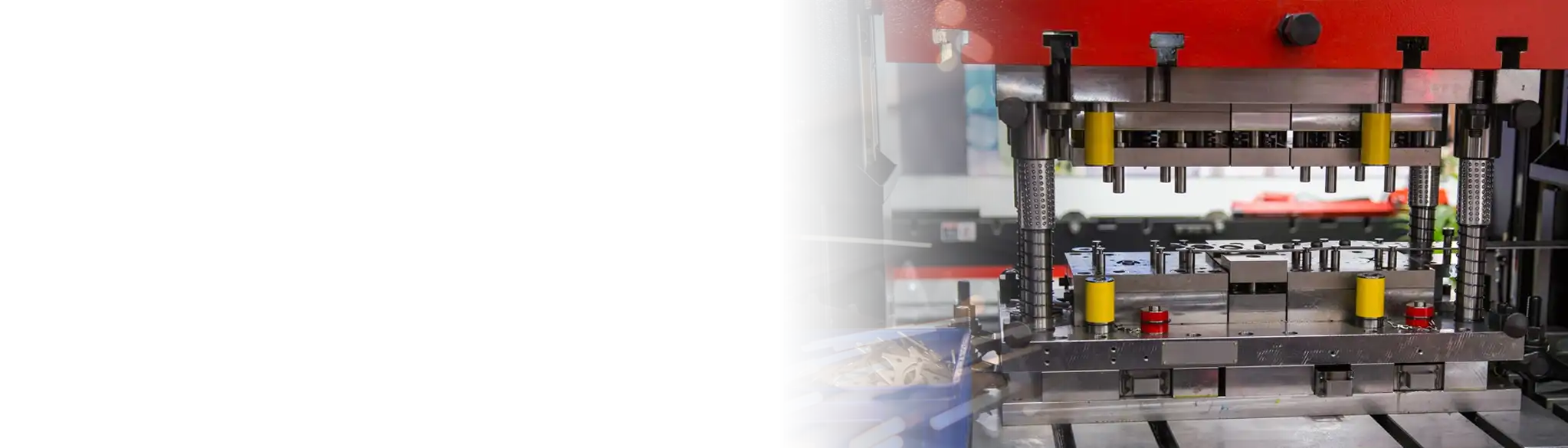

Sheet Metal Stamping Services for Industrial Applications

High-speed stamping for high-volume sheet metal components and custom hardware integration. From 500 units, repeatable geometry with integrated fasteners and reinforcing features. Die design in 2–4 weeks; 48h DFM & quote.

Accepted Formats: STEP · IGES · DWG · PDF

Custom Design & Engineering Support

From simple brackets to complex formed components, our engineering team evaluates your designs for manufacturability, die design efficiency, and tooling investment optimization.

We work directly with your CAD models to optimize geometry for progressive or single-station stamping, analyze material flow for deep-draw operations, and integrate hardware features during the stamping process to eliminate secondary operations.

- Geometry optimization for progressive die design

- Material flow analysis and draw depth evaluation

- Hardware location and integration planning

- Reinforcing rib and emboss design for strength optimization

- Production volume analysis to justify die investment

Workflow: Upload design → 48h feasibility & DFM feedback → Detailed quote with tooling cost → Die fabrication → First article validation → Production

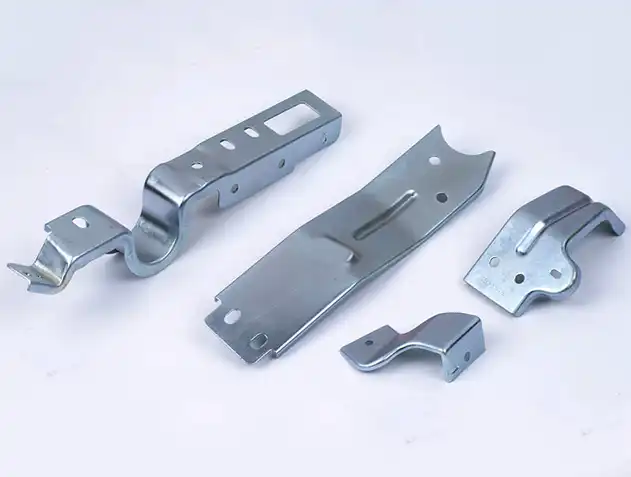

Work Samples

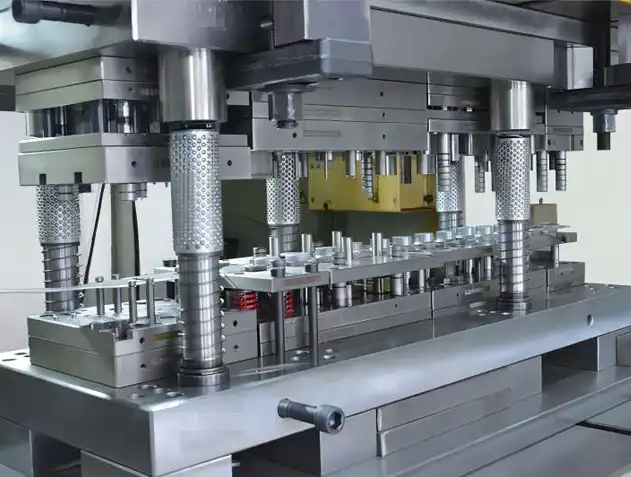

Representative examples of our sheet metal stamping work. These samples showcase precision die design, progressive stamping, and integrated hardware installation.

Stamping Capabilities

From high-speed progressive stamping to custom single-station dies, our stamping systems deliver cost-effective volume production with integrated hardware and complex geometry.

Progressive & Single-Station Stamping

High-speed stamping for volume production. Progressive dies process multiple features in single press stroke, dramatically reducing cycle time and cost per piece.

Complex Geometry Development

Reinforcing ribs, embosses, and integrated flanges add strength without weight. Custom geometry delivers functional advantages and cost optimization.

Hardware Integration

Self-clinching fasteners, threaded inserts, and formed holes integrated during stamping. Eliminates secondary assembly and reduces overall component cost.

Materials & Technical Capabilities

Material Compatibility

Our stamping systems handle a wide range of sheet metal materials, each optimized for specific applications and volume requirements.

- Mild steel and carbon steel

- Stainless steel (304, 316)

- Aluminum alloys (1100, 5052, 6061)

- Brass and copper

Material selection affects die design, spring-back characteristics, and cycle time. Our team provides guidance during the DFM review.

Technical Specifications

- Minimum volume:500+ units recommended

- Material thickness:0.5 mm – 6 mm

- Tolerance:±0.2–0.5 mm typical

- Die lead time:2–4 weeks

All specifications confirmed at quote based on part geometry, material selection, and production volume.

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Related Products

Quality Assurance & Inspection

Every stamped component undergoes rigorous inspection for dimensional accuracy, geometry consistency, and hardware installation to ensure consistent quality throughout production runs.

First Article & Production Inspection

Our quality systems ensure first articles meet specifications and maintain consistency throughout production. For high-volume production, we implement Statistical Process Control (SPC) to monitor die wear and maintain quality across millions of parts.

- First Article Inspection (FAI) with full dimensional report

- In-process geometry verification during production

- Statistical Process Control (SPC) for high-volume runs

- Hardware installation verification and pull testing

- Final dimensional and visual inspection against drawing specs

Documentation & Traceability

We provide complete quality documentation with full traceability through our ISO 9001 compliant quality management system.

- First Article Inspection (FAI) with full dimensional reports

- In-process dimensional verification during production

- Statistical Process Control (SPC) for high-volume runs

- Certificate of Conformance (CoC) on request

- Material certifications and Certificates of Analysis (CoA)

Why Partner with X-KPR

When high-volume stamping needs precision, rapid die development, and cost-effective production, X-KPR delivers proven results and transparent tooling investment analysis.

Fast Turnaround

Die design and fabrication completed within 2–4 weeks. First parts ready for validation quickly.

Cost-Effective at Scale

High-speed stamping dramatically reduces per-piece cost at volume. Tooling investment amortized across large production runs.

Repeatable Precision

Die-driven accuracy ensures identical geometry across millions of parts. Perfect for critical applications requiring consistency.

Frequently Asked Questions

What are typical die costs for stamping?

What is the minimum production volume?

Can you stamp stainless steel and aluminum?

What hardware integration options are available?

How are tolerances controlled in stamping?

What about production lead time?

Request a Quote

Share your part geometry, material specifications, thickness requirements, hardware integration needs, and expected volume. We'll provide detailed DFM feedback and a comprehensive quote within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.