Tube Fabrication Services

Integrated tube processing for marine, aerospace, and industrial applications.

Upload STEP/IGES/DWG for DFM feedback and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

We process tubular stock through a complete fabrication sequence—laser cutting, CNC bending, end forming, and welding. These integrated capabilities produce precision frameworks, roll cages, railings, and complex three-dimensional structures from a single source.

- Laser tube cutting with rotary axis

- CNC mandrel bending for tight radii

- Flaring, swaging, and end forming

- TIG/MIG welding for structural joints

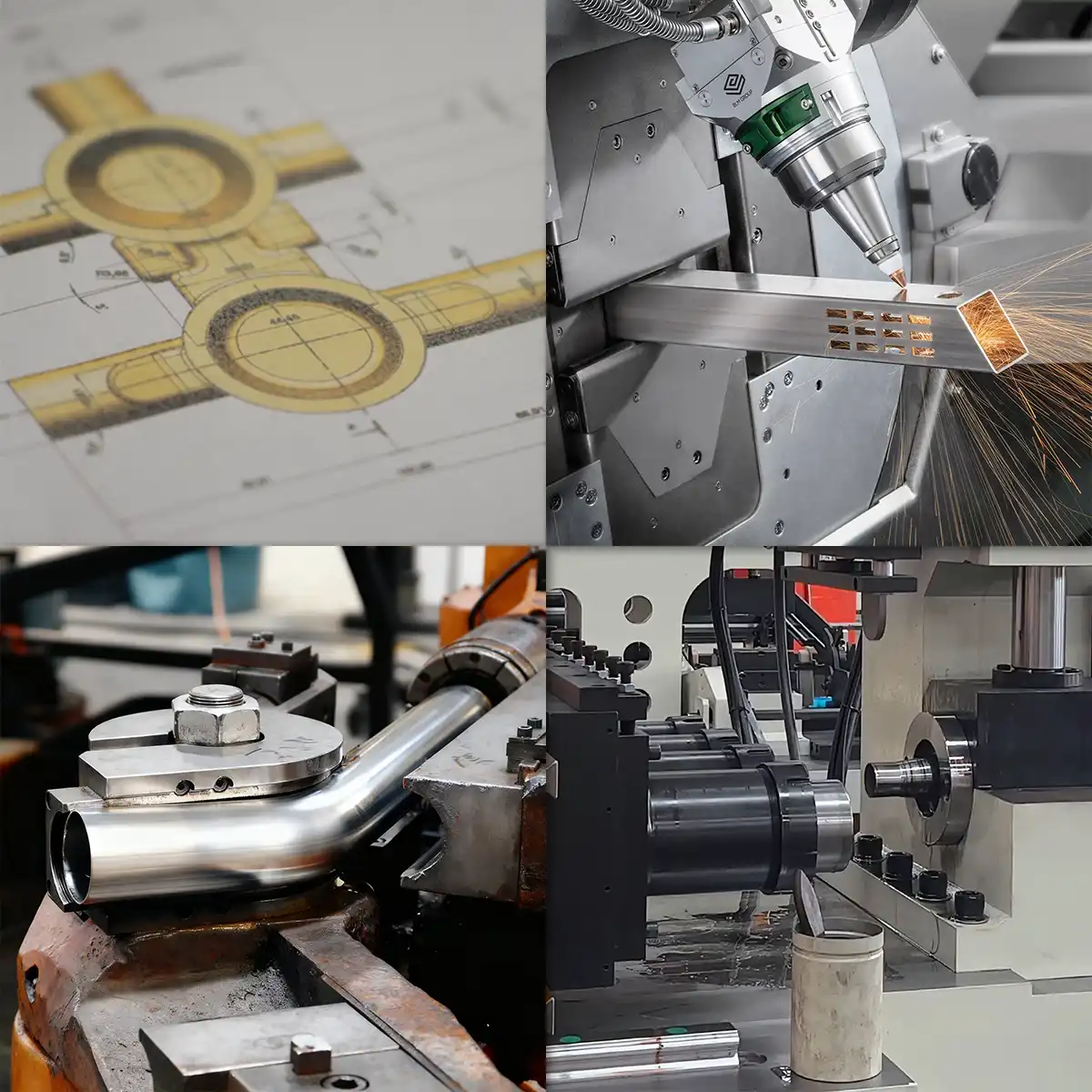

Tube Processing Capabilities

Explore our core tube fabrication services—each optimized for precision, repeatability, and quality assurance.

Laser Tube Cutting

Rotary-axis laser cutting with ±0.05mm precision for complex tube geometries.

Tube Bending

CNC mandrel bending delivering smooth curves with minimal wall thinning.

Tube Flaring

Precision flaring and swaging for hydraulic and plumbing connections.

Tube Welding

TIG/MIG welding with full traceability and quality documentation.

Custom Tube Fabrication

End-to-end tube product manufacturing with DFM review.

Integrated Tube Fabrication Workflow

From raw tube stock to finished assembly—single-source manufacturing eliminates handoffs and accelerates delivery.

Laser Cutting

Rotary-axis laser cutting with ±0.05mm precision for complex tube geometries.

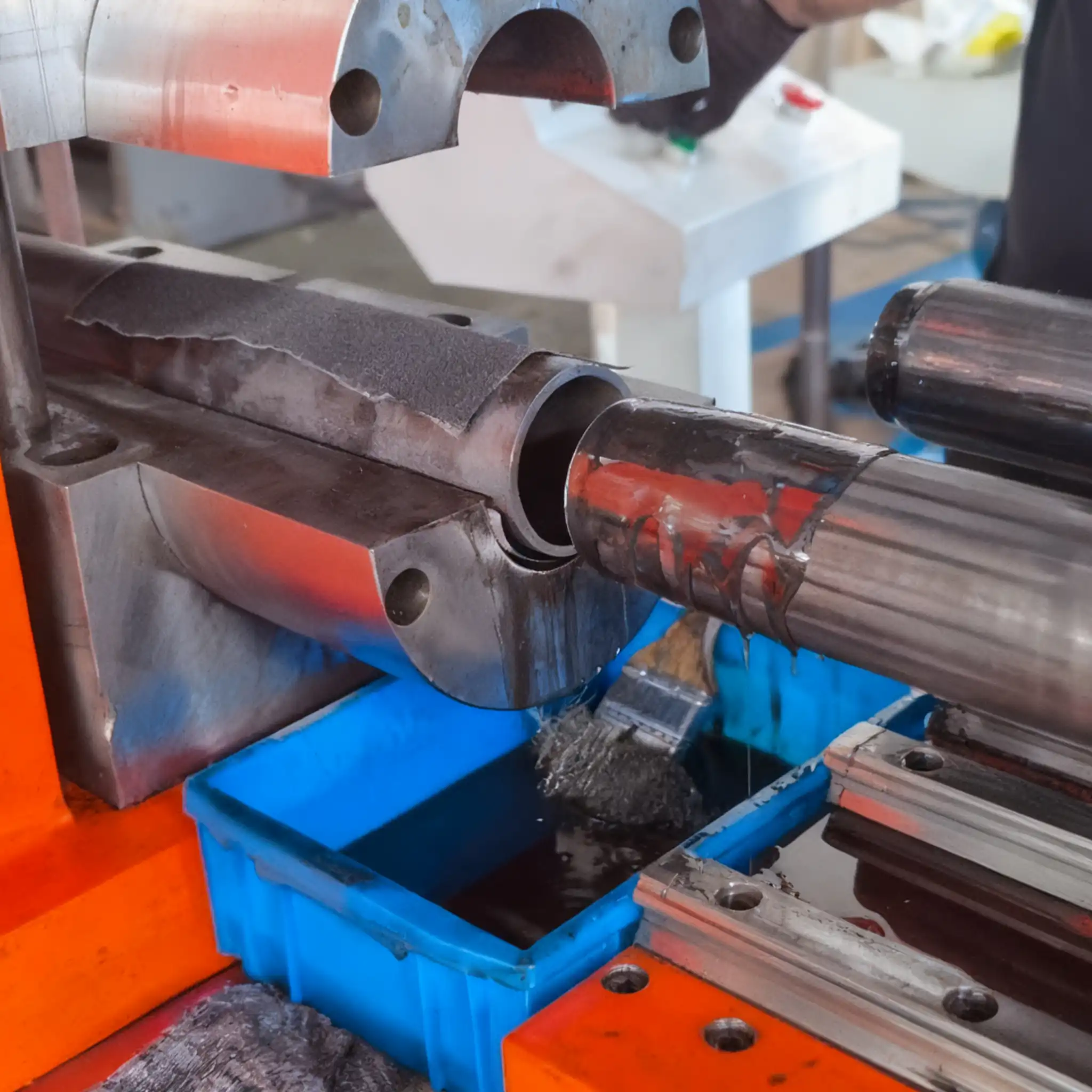

CNC Bending

Mandrel bending ensures smooth curves with minimal wall thinning.

Flaring & Forming

Precision flaring and end forming for connection interfaces.

Welding & Assembly

TIG/MIG welding with full traceability and dimensional verification.

Products Using Tube Fabrication

See how our tube fabrication capabilities come together in finished marine products.

Tops & Towers

T-tops, radar towers with integrated electronics mounting.

Bow Pulpits

Multi-tube bow pulpit assemblies with anchor roller integration.

Stern Pulpits

Custom stern pulpit fabrication with matching bow rail design.

Bimini Frames

Lightweight bimini frames with precision tube bending.

Rocket Launchers

Rod holder systems for fishing vessels.

Hardtops

Fixed hardtop structures with integrated electronics mounting.

Radar Arches & Supports

Custom radar arch and support structures for marine vessels.

Rails & Deck Fittings

Custom bow rails, safety railings, and integrated deck hardware.

Seating & Leaning Posts

Custom seating frames and leaning posts with integrated storage.

Request a Quote

Tell us your tube specifications, geometry, and quantities. We'll return DFM notes and a firm quote within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.