Precision Tube Notching Services

CNC tube notching for clean saddle joints, cope cuts, and miter connections. Supports 316L stainless steel for marine applications, aluminum alloys, and carbon steel.

Upload STEP/IGES/DWG for DFM feedback and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

DFM Review & Engineering Support

Every tube notching project begins with engineering analysis. We evaluate your joint geometry for optimal notch profiles, fit-up tolerances, and weld access.

- Tube diameter, wall thickness, and material specification

- Joint angle and notch type (saddle, cope, miter)

- Fit-up tolerance requirements for welding

- Number of notches per tube and spacing

- Quantity and delivery timeline

Workflow: Upload design → 48h feedback → Quote with DFM notes → Prototype or production run

Work Samples

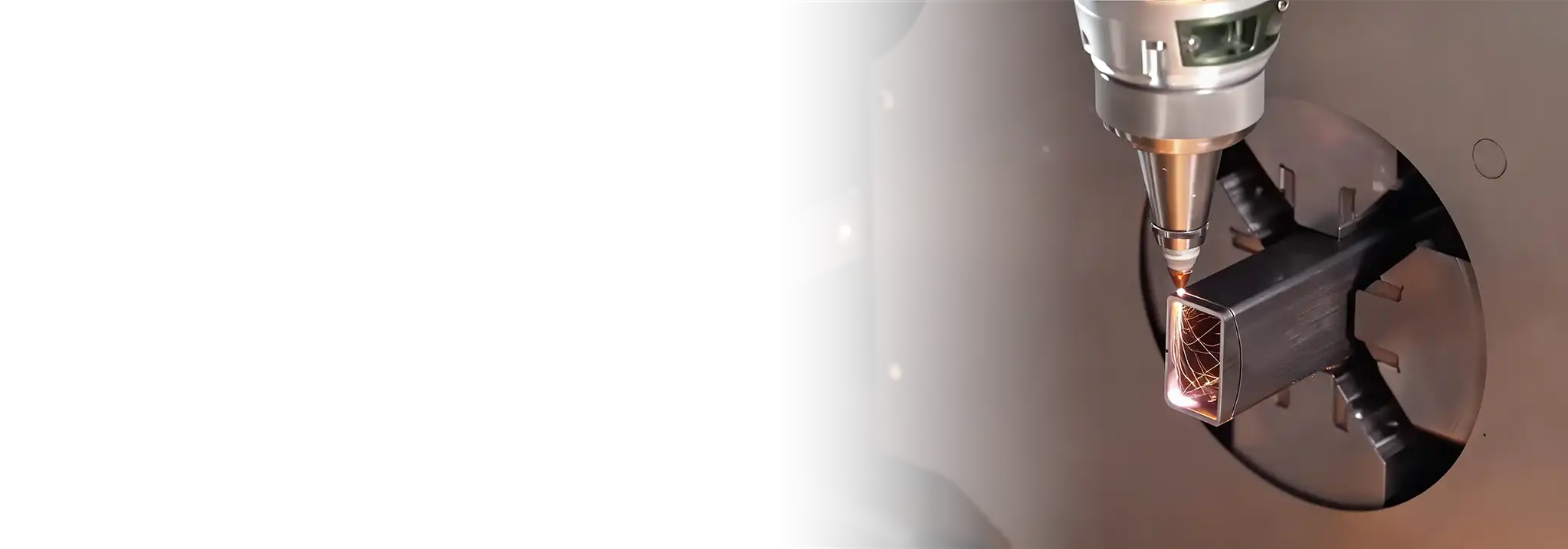

Representative examples of our tube notching capabilities. These samples showcase precision saddle joints and cope cuts for various applications.

Technical Capabilities

Notching Process

We process a wide range of tube materials, with particular expertise in marine-grade stainless steel for corrosion resistance.

Precision Standards

- Tube OD range:0.5" – 6" (12 – 150 mm)

- Wall thickness:0.065" – 0.375" (1.6 – 10 mm)

- Notch angle tolerance:±0.5°

- Fit-up gap:<0.5 mm

Materials

- Stainless steel (304, 316, 316L)

- Aluminum alloys (6061-T6, 5083-H116)

- Carbon steel (A36, 1018)

- Chrome-moly (4130)

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Products Using This Capability

Quality Assurance

Quality processes aligned with ISO 9001 standards.

Inspection & Verification

- First Article Inspection (FAI) for every new part

- In-process fit-up verification with gauge tubes

- Angular measurement with digital protractor

- Visual inspection for burr-free edges

- Sample weld test for critical applications

Quality Documentation

We provide FAI reports, in-process inspection logs, Certificate of Conformance (CoC), and material certifications on request.

Certification: Quality processes aligned with ISO 9001 standards.

Why Choose X-KPR for Tube Notching

When precision tube joints drive your project quality, X-KPR combines engineering expertise, precision equipment, and documented quality control.

Engineering-Driven DFM Review

Our engineers evaluate joint designs for optimal notch configuration and weld access—48h turnaround.

Precision Fit-Up

Standard fit-up gap <0.5 mm ensures clean TIG welds with full penetration on first pass.

ISO 9001 Quality Assurance

FAI verification with digital angle measurement. Traceable inspection records.

Frequently Asked Questions

What types of notches can you produce?

What is the fit-up tolerance for welding?

Do you provide DFM review for tube notching?

What materials can you notch?

What is the typical lead time?

Request a Quote

Provide tube specifications, joint angles, and quantities. We'll return DFM notes and a firm quote within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.