Custom Bimini Frames for Marine Vessels

Lightweight aluminum and stainless steel bimini top frames with precision arch bending, integrated folding mechanisms, and marine-grade finishing.

Upload STEP/IGES/DWG for DFM feedback and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

Design & Engineering Collaboration

Bimini frames must balance lightweight construction with structural rigidity under wind and canvas tension loads. Our engineering review optimizes arch geometry, tube selection, and folding mechanisms for your specific application.

We evaluate mounting point loads, fold clearances, and headroom requirements to deliver frames that perform reliably and stow compactly.

- Beam width and mounting point locations

- Desired shade coverage dimensions

- Folding configuration (2-bow, 3-bow, 4-bow)

- Headroom and clearance requirements

- Material preference and finish

Workflow: Upload design → 48h feedback → Quote with DFM notes → Prototype or production run

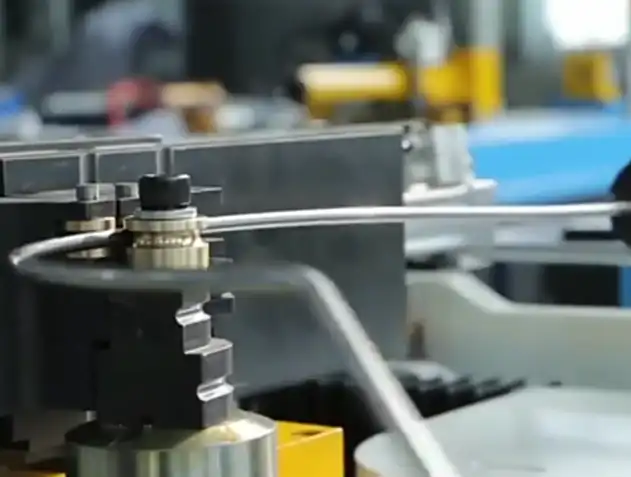

Work Samples

Representative examples of our bimini frame fabrication. These samples showcase the precision arch bending, hinge integration, and marine-grade finishing that goes into every frame we build.

Materials & Marine-Grade Finishing

Frame Materials

6061-T6 Aluminum — Lightweight and corrosion-resistant with anodized finish. Standard choice for most bimini applications where weight matters.

316 Stainless Steel — Maximum corrosion resistance for harsh saltwater environments. Heavier but offers superior long-term durability.

Surface Finishing Options

- Clear anodizing for natural aluminum appearance

- Black anodizing for UV resistance and aesthetics

- Powder coating for custom color matching

- Mirror or brushed polish for stainless steel frames

All finishes engineered for UV exposure and marine environment durability.

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Related Products

Quality Assurance

Every bimini frame undergoes arch profile verification, hinge alignment checks, and folding operation testing before shipping.

Precision Standards

- Arch profile:±1.0–2.0 mm (span-dependent)

- Tube bending:angular deviation ≤ 0.3–0.5°

- Hinge alignment:±0.5 mm

- Overall dimensions:±2.0 mm (confirmed at quote)

Quality Documentation

- Arch profiles verified against design templates

- Folding operation tested for smooth action and proper clearances

- Finish quality inspected for uniformity and defects

- Bending fixtures ensure consistent arch geometry across production batches

- Certificate of Conformance (CoC) on request

Process Control: Bending fixtures ensure consistent arch geometry across production batches.

Why Partner with X-KPR

Bimini frames require precise arch geometry and reliable folding mechanisms. X-KPR combines engineering expertise, precision bending, and integrated manufacturing for production-ready frames.

Engineering-First Approach

DFM feedback within 48h evaluates arch geometry, folding mechanism clearances, and mounting interfaces.

Weight-Optimized Design

Material selection and wall thickness optimization reduce frame weight without compromising structural rigidity.

Complete Frame Assembly

Tube bending, joint fabrication, hinge integration, and finishing delivered as complete assemblies.

Frequently Asked Questions

What materials are used for bimini frames?

What tube diameters are available?

Can you manufacture folding bimini frames?

What is the typical lead time?

Do you provide mounting hardware?

Request a Quote

Provide your bimini frame requirements, dimensions, and folding configuration. We'll return engineering feedback and a detailed quote within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.