Custom Bow Pulpits for Marine Vessels

Complex multi-tube bow pulpit frameworks with precision tube bending, structural welding, and marine-grade finishing.

Upload STEP/IGES/DWG for DFM feedback and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

Design & Engineering Collaboration

Bow pulpits require precise geometry to match deck contours, distribute loads correctly, and integrate with existing deck hardware. Our engineering review ensures manufacturability before production begins.

We evaluate tube routing, joint configurations, and mounting interfaces to optimize structural performance while minimizing fabrication complexity and cost.

- 3D CAD or detailed drawings with dimensions

- Deck mounting pattern and hardware specifications

- Material preference (stainless steel or aluminum)

- Integration points (anchor roller, lights, cleats)

Workflow: Upload design → 48h feedback → Quote with DFM notes → Prototype or production run

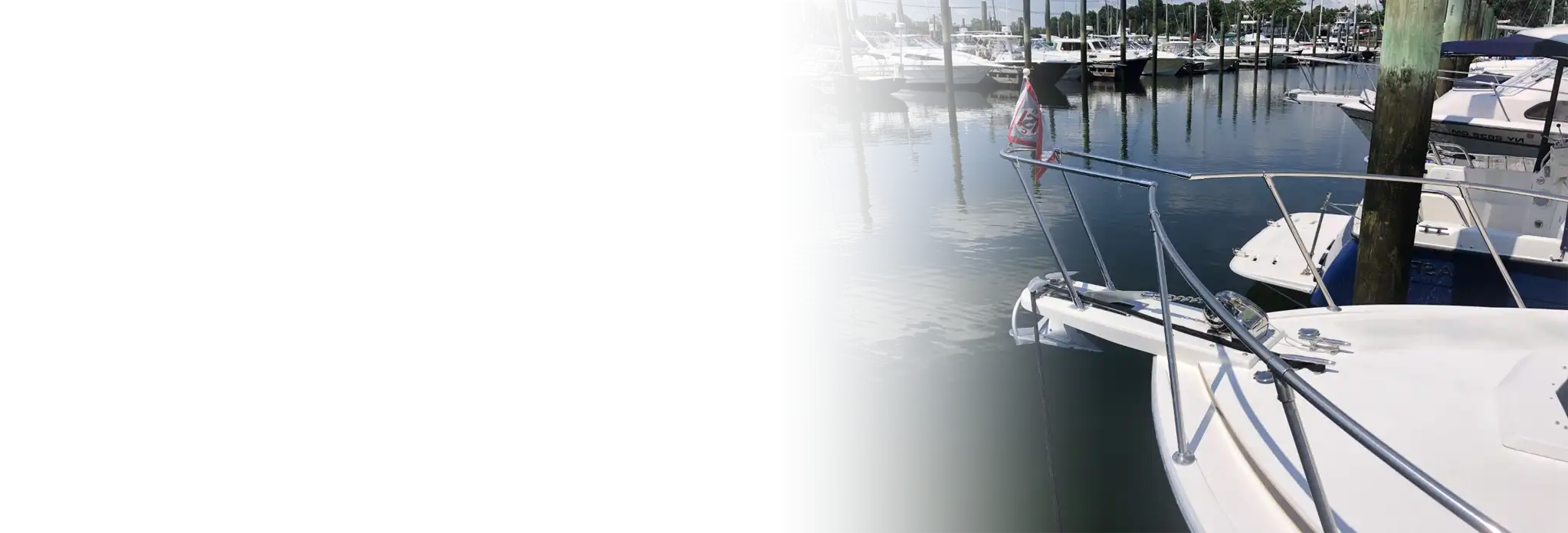

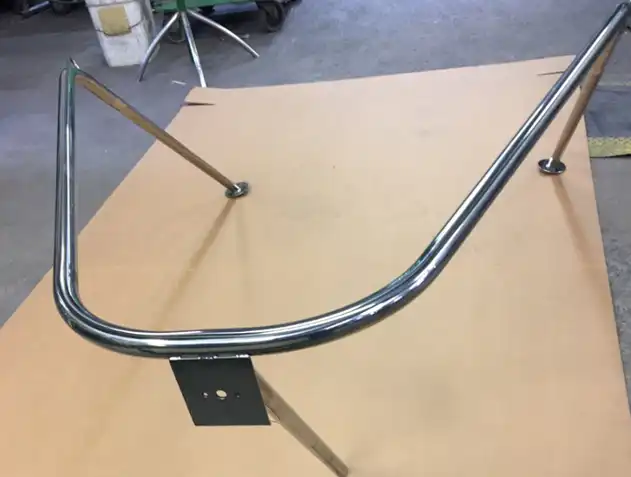

Work Samples

Representative examples of our bow pulpit fabrication. These samples showcase the precision tube bending, welding, and finishing that goes into every structure we build.

Fabrication Capabilities

Integrated tube processing from cutting through welding and finishing. Custom fixtures ensure consistent quality across complex multi-tube assemblies.

Complex Tube Bending

CNC mandrel bending creates smooth compound curves for bow pulpit rails while maintaining wall integrity and consistent cross-sections.

Precision Tube Cutting

Laser tube cutting delivers clean miter joints and mounting interfaces with ±0.05–0.1 mm accuracy for seamless assembly.

Structural Welding

TIG welding on stainless steel and aluminum creates strong, clean joints with full penetration for marine structural loads.

Materials & Surface Finishing

Marine-Grade Materials

- 316 stainless steel for maximum corrosion resistance

- 6061-T6 aluminum for weight-optimized applications

- Custom tube diameters from 22mm to 32mm OD

- Wall thickness options from 1.5mm to 3mm

Material selection guidance provided during DFM review based on your application requirements.

Surface Finishing Options

- Mirror polish for premium stainless steel appearance

- Brushed satin finish for reduced glare and maintenance

- Type II/III anodizing for aluminum corrosion protection

- Powder coating for custom color matching

All finishes engineered for long-term marine exposure and UV resistance.

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Related Products

Quality Assurance

Every bow pulpit undergoes dimensional verification and weld inspection before shipping. Custom fixtures ensure consistent geometry across production quantities.

Precision Standards

- Tube bending:angular deviation ≤ 0.3–0.5°

- Laser cutting:±0.05–0.1 mm

- Weld assembly:±0.5–1.0 mm (fixture-controlled)

- Overall dimensions:±1.0–2.0 mm (confirmed at quote)

Quality Documentation

- First Article Inspection (FAI) with dimensional reports

- In-process inspection at critical fabrication stages

- Final dimensional verification before shipment

- Certificate of Conformance (CoC) on request

- Material certifications and traceability documentation

Process Control: Custom welding fixtures maintain joint positioning and angular accuracy across all production units.

Why Partner with X-KPR

Complex tube frameworks require integrated manufacturing capabilities. X-KPR combines engineering expertise, precision equipment, and quality systems to deliver production-ready bow pulpits.

Engineering-First Approach

DFM feedback within 48h evaluates load paths, joint stress, and manufacturability before production starts.

Structural Integrity

Custom fixtures ensure consistent weld positioning and dimensional accuracy across production runs.

Integrated Manufacturing

Tube cutting, bending, welding, and finishing in one facility for streamlined delivery.

Frequently Asked Questions

What materials are used for bow pulpits?

What tube diameters and wall thicknesses are available?

Can you match existing deck hardware patterns?

What is the typical lead time?

Do you provide installation hardware?

What tolerances can you hold for tube assemblies?

Request a Quote

Provide your bow pulpit design, material preference, and quantity requirements. We'll return DFM feedback and a detailed quote within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.