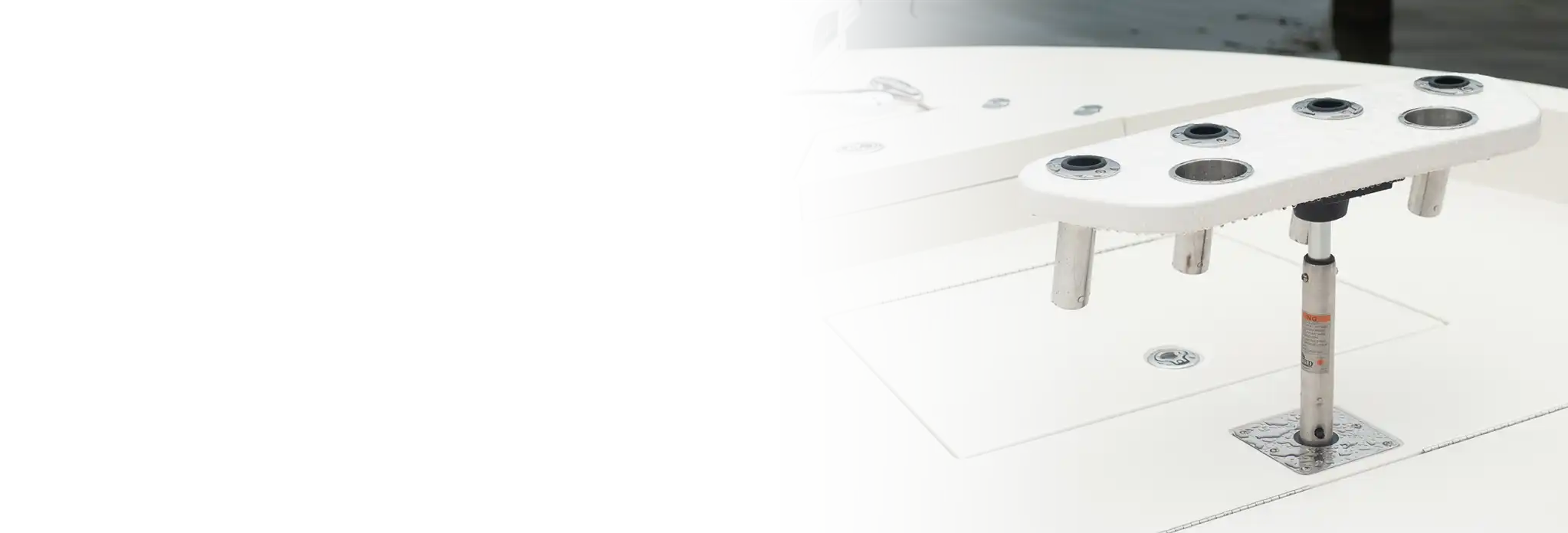

Custom Rocket Launchers for Marine Vessels

Multi-rod rocket launcher assemblies with precision tube bending, structural welding, and marine-grade finishing. Engineered for T-top, hardtop, and leaning post integration. Upload STEP/IGES/DWG — 48h DFM & quote.

Design & Engineering Support

Rocket launchers must present rods at optimal angles while integrating structurally with T-tops, hardtops, or leaning posts. Our engineering review ensures proper load transfer and precise mounting fit.

We evaluate rod angles, tube spacing, and mounting geometry to deliver assemblies that perform under real fishing conditions—rod weight, boat motion, and fish strikes.

- Number of rod holders required

- Mounting location and interface geometry

- Desired rod angles and spacing

- Integration with existing structure (T-top, hardtop, etc.)

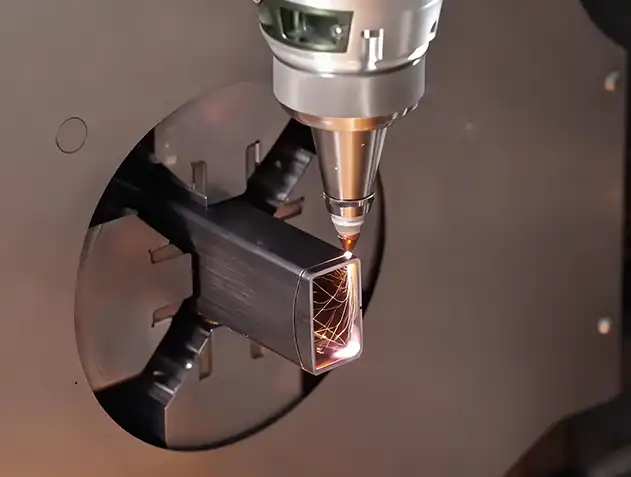

Manufacturing Process Gallery

See our rocket launcher fabrication process—precision tube bending, fixture-controlled welding, and marine-grade finishing.

Materials & Surface Finishing

Marine-Grade Materials

316 Stainless Steel — Standard for offshore fishing applications. Superior corrosion resistance and structural strength for heavy rod loads and aggressive fish strikes.

6061-T6 Aluminum — Lightweight option with anodized finish. Suitable for inshore applications and weight-sensitive installations.

Finishing Options

- Mirror polish for premium stainless steel appearance

- Brushed satin finish for reduced glare

- Clear or black anodizing for aluminum

- Powder coating for custom color matching

All finishes engineered for saltwater exposure and UV resistance.

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Quality Assurance

Every rocket launcher undergoes angle verification, weld inspection, and mounting interface checks before shipping. Fixtures ensure consistency across batches.

Precision Standards

- Rod holder angle:±0.5° (fixture-controlled)

- Tube spacing:±1.0 mm

- Mount interface:±0.5 mm

- Overall dimensions:±2.0 mm (confirmed at quote)

Quality Verification

Rod holder angles verified against specification. Weld penetration inspected for structural integrity. Mount interfaces checked for precise fit with existing structures.

Process Control: Welding fixtures maintain tube angles and spacing across all production units.

Why Partner with X-KPR

Rocket launchers require precise angles and structural integration. X-KPR combines engineering expertise, precision fabrication, and quality systems for production-ready rod management solutions.

Engineering-First Approach

DFM feedback within 48h evaluates rod angles, mounting interface geometry, and structural integration for optimal manufacturability.

Consistent Quality

Fixture-controlled welding ensures consistent tube angles and joint quality across all production units.

One-Stop Fabrication

Integrated workflow covering tube bending, cutting, welding, and finishing for rocket launchers and integration structures.

Frequently Asked Questions

What materials are used for rocket launchers?

What rod holder tube diameters are available?

Can you match existing T-top or hardtop mounting?

What rod angles are standard?

What is the typical lead time?

Request a Quote

Provide your rocket launcher requirements, mounting details, and integration needs. We'll return engineering feedback and a detailed quote within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.