Custom Tops & Towers for Marine Applications

Precision-engineered marine structures with ±0.5–1.0 mm tolerances.

Upload STEP/IGES/DWG for DFM feedback and quote within 48 hours.

Accepted Formats: STEP · IGES · DWG · SLDPRT · PDF

Design & Engineering Collaboration

Every successful marine structure starts with engineering insight. We work directly with your CAD drawings to evaluate geometry, load paths, and structural integrity before fabrication begins.

Our team provides DFM feedback within 48 hours, recommending modifications that improve manufacturability without compromising functionality.

- CAD modeling & design adaptation

- Material & process selection guidance

- FEA structural validation (on request)

- Cost-optimized manufacturing strategies

Workflow: Upload design → 48h feedback → Quote with DFM notes → Prototype or production run

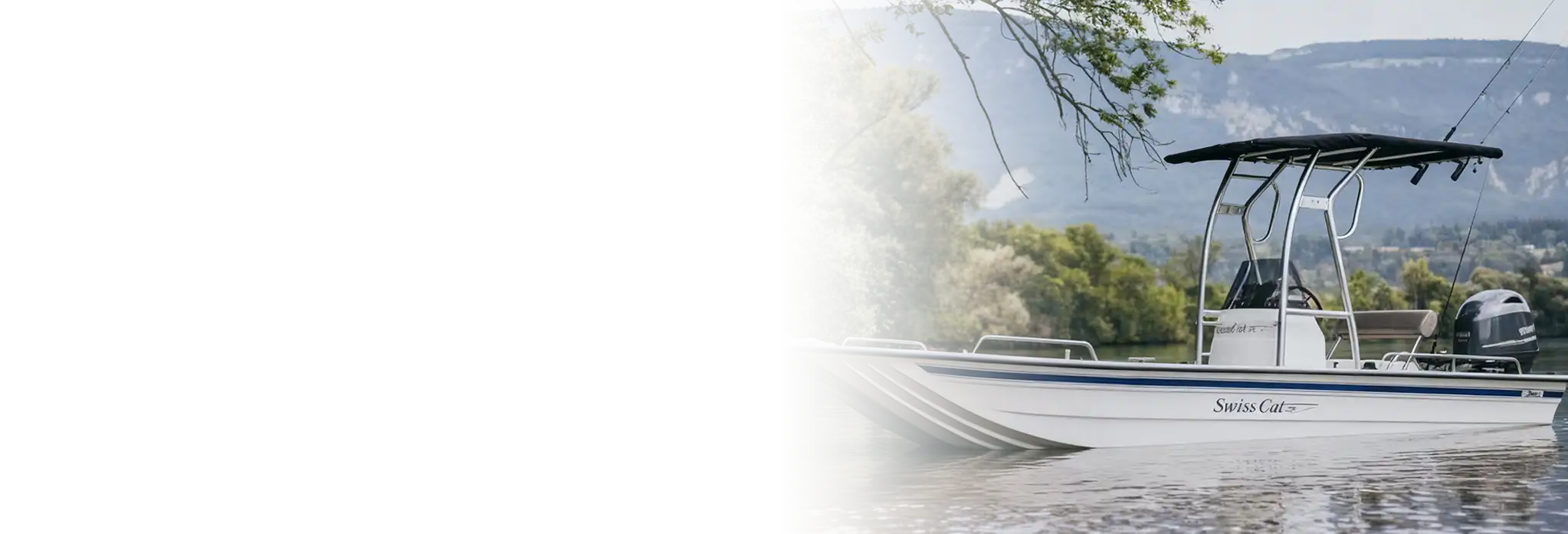

Work Samples

Representative examples of our marine tops and towers fabrication. These samples showcase the precision tube bending, welding, and finishing that goes into every structure we build.

Materials & Marine-Grade Finishing

Materials

We specialize in marine-grade stainless steel assemblies (304/316) and anodized aluminum frameworks (6061-T6) for lightweight yet corrosion-proof results.

Material selection depends on application environment, load requirements, and finishing preferences. Our team provides guidance during the engineering review phase.

Surface Finishing Options

- Mirror or brushed polishing for premium aesthetics

- Anodizing (Type II/III) for long-term corrosion defense

- Powder coating for custom color finishes

- Marine-grade treatments for saltwater environments

The result: structures that perform under pressure — and look flawless above deck.

Related Capabilities

Tube Fabrication

Laser cutting, CNC bending, flaring, and precision welding for tube structures.

Sheet Metal Fabrication

Laser cutting, press brake bending, stamping, and enclosure assembly.

CNC Machining

Precision milling, turning, and prototyping for complex geometries.

Welding & Assembly

TIG, MIG, laser welding with complete mechanical assembly services.

Surface Finishing

Powder coating, anodizing, polishing, and plating for corrosion protection.

Tooling Quality & Automation

Custom tooling, CMM inspection, and process automation solutions.

Related Products

Quality Assurance

Precision is measured, not claimed. Each assembly undergoes full dimensional verification, weld integrity checks, and surface inspection before delivery.

Precision Standards

- Tube fabrication:±0.5–1.0 mm (confirmed at quote)

- Laser cutting:±0.05–0.1 mm

- CNC bending:angular deviation ≤ 0.3–0.5°

- Welding assembly:±0.5–1.0 mm (joint-dependent)

Quality Documentation

We provide FAI reports, in-process inspection logs, Certificate of Analysis (CoA), Certificate of Conformance (CoC), and CMM reports on request.

Certification: ISO 9001 compliant quality management system with traceable inspection records.

Why Partner with X-KPR

When complex tube assemblies need to move from design to production-ready parts, X-KPR brings engineering rigor, integrated capabilities, and proven quality systems.

Engineering-First Approach

DFM feedback within 48h helps de-risk designs before production starts.

Consistent Quality

ISO 9001 processes ensure traceable inspections and dimensional consistency.

One-Stop Fabrication

Integrated workflow covering tube bending, cutting, welding, and finishing.

Frequently Asked Questions

What materials are suitable for marine tops & towers?

Can I send my CAD files directly?

What is the typical lead time?

Do you support small batch production?

What tolerances can you hold for tube assemblies?

Request a Quote

Tell us your material, dimensions, key features, and quantities. We'll return DFM notes and a firm quote within 48 hours.

Accepted: STEP · IGES · DWG · SLDPRT · PDF

Request a Quote

Upload your designs and tell us about your project. We'll return DFM feedback and a detailed quote within 48 hours.